Technical Talk With David Biggs

Words: David BiggsBonding with Masonry

By David Biggs

Welcome back! It was good to hear from many of you that you are reading this column and want to participate.

Q: This first question comes from two perspectives. The first is from a structural engineer and the second from a contractor.

- I have seen standard details where the horizontal reinforcement is stopped at vertical movement joints (control joints) in CMU walls but I’ve also seen where some designers continue the reinforcement through the joint. What is the correct method?

- As contractors, we have noticed that architects and engineers often detail the CMU bond beam reinforcement at control joints differently. Why can’t the detail always be the same?

A: Good points! You’d think one detail is good enough, but it’s not that simple.

Let’s start by discussing the reason for a movement joint in the first place. In masonry, joints accommodate movement of the masonry due to either expansion or contraction. These are not to be confused with building joints that isolate whole building segments from differential movements caused by swaying from wind or seismic effects.

While clay masonry generally expands, CMU walls primarily shrink due to moisture shrinkage, thermal effects and carbonation. To prevent shrinkage-induced CMU cracking, designers have to either a) specify movement joints (control joints) or b) horizontally reinforce the walls to minimize any vertical cracking.

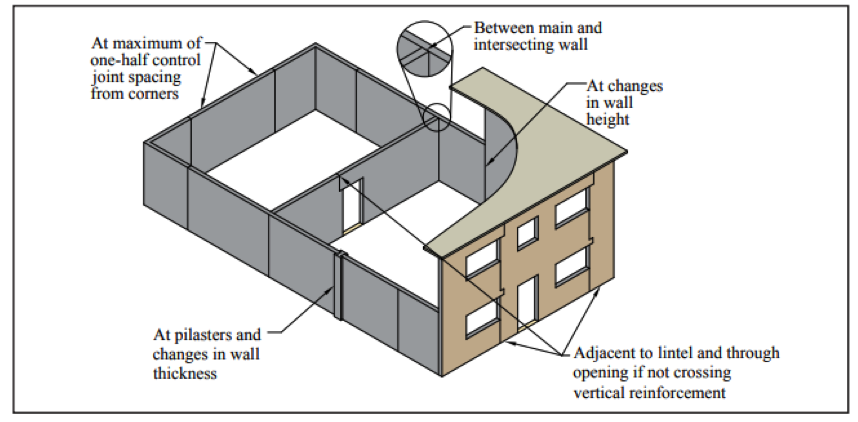

For CMU movement joints, the National Concrete Masonry Association (NCMA) provides TEK Notes with design techniques for determining the joint spacing and locations. TEK 10-01A provides an excellent overview of CMU crack control. TEK 10-2C then illustrates recommendations for placing joints that provide relief at naturally occurring stress locations (see Figure 1). The locations are valid for unreinforced masonry. While they are also applicable to reinforced masonry, designers often modify these based upon their individual experience. This TEK also provides empirical recommendations for joint spacings and horizontal reinforcement.

Figure 1 – Typical Joint Locations (credit NCMA TEK 10-2c)

Figure 1 – Typical Joint Locations (credit NCMA TEK 10-2c)

Finally, TEK 10-3 provides an alternative-engineered method for extending joint spacings through increased use of horizontal reinforcement. This method uses scientific procedures and material properties to determine joint spacings rather than empirical methods.

Up until now, all the movement joints we’ve discussed are to prevent shrinkage cracking. None of the reinforcement (horizontal joint reinforcement or bond beam reinforcement) need extend through the joints. Each wall panel is isolated from the adjacent panel by the joint.

However, that’s not the end of the story. Sometimes, we need reinforcement to pass through the joints to transfer loads. That’s where we break the isolation rule and create the confusion that led to the questions.

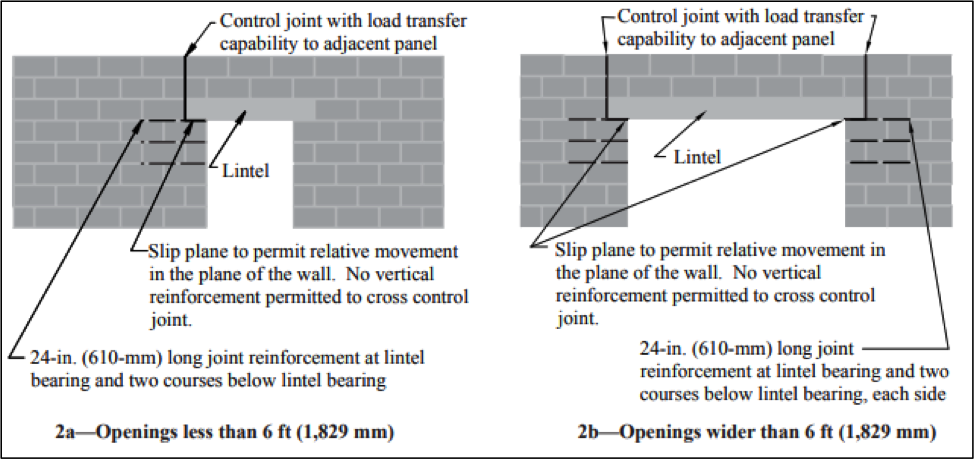

Under what circumstances do we need load transfer through a control joint? Figure 2 is taken from TEK 10-2C. It illustrates options for bracing the masonry above openings. Since the lintels need to slip, the wall area above the lintels must span horizontally. Therefore, the reinforcement needs to extend through the control joints to transfer out-of-plane shear. The reinforcement should only extend through the joint sufficiently for shear. If the reinforcement extends enough to develop it in tension, cracking could occur. So, it’s a delicate balance to transfer shear and still minimize restraint that might cause shrinkage cracking.

Figure 2 – Openings (credit NCMA)

Figure 2 – Openings (credit NCMA)

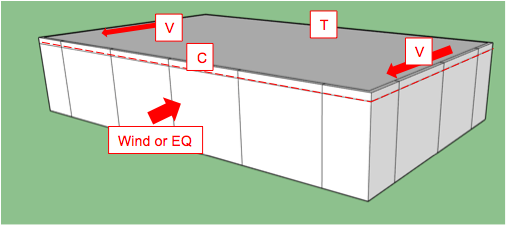

Another example of load transfer occurs at some buildings with bond beams at floor and roof levels. Figure 3 shows a conceptual CMU building with control joints. While the loads are shown in one direction, the same type of loading occurs transversely. In either case, the overall bracing relies on the roof diaphragm.

Figure 3 – Bearing wall building and roof diaphragm

Figure 3 – Bearing wall building and roof diaphragm

The bond beams (in red) are typically the chords of the roof diaphragm. They must take the tension (T) and compression (C) of the diaphragm and transfer shear (V) to the side walls. The bond beams transfer the forces. Therefore, the reinforcement in the bond beams must be continuous at the joints since the bars transfer tension and/or shear through the joint.

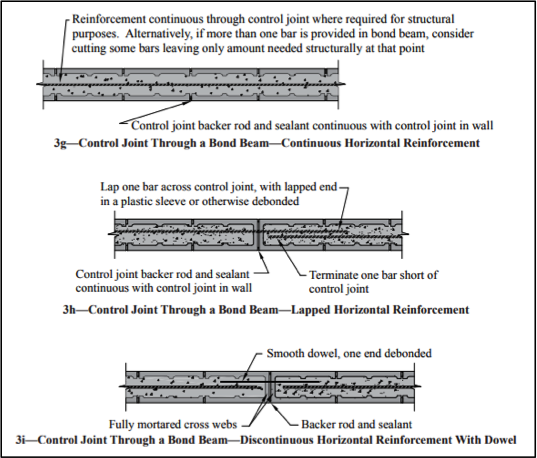

Figure 4 shows several bond beam details from TEK 10-2C where load is transferred through the control joint. Detail 3g is continuous through the joint and transfers tension and shear. Detail 3h has a bar extended through the joint but the extension is debonded with a plastic sleeve. This detail can only transfer out-of-plane shear. Detail 3i uses a dowel with one end debonded to again only transfer out-of-plane shear.

Figure 4 – Bond beam Details (credit NCMA)

Figure 4 – Bond beam Details (credit NCMA)

For steel-framed buildings with a CMU exterior, the perimeter steel functions as the chords of the floor and roof diaphragms. The reinforcement in CMU bond beams are not needed for chord forces and can be discontinuous.

These examples demonstrate that engineers must first determine whether load must be transferred through the movement joint and then detail the reinforcement accordingly.

Q: For my building designs, I have never specified couplers for bar splices. When should I put couplers into my specifications?

A: The choice of using couplers (mechanical splices) is most often a means and methods selection by the mason contractor based upon economics. Designers are not required to specify couplers but they may.

Contractors usually compare the cost of the added materials to create lap splices as well as the labor to install longer bars and to sequence the grouting. Couplers usually have an added material cost in comparison to added bar lengths. But, labor costs could be lower. Since 2003, lap splices have increased for larger bars sometimes exceeding the lift height for grout placement. Thus, couplers become more attractive as a splicing option in comparison to large laps. Each contractor makes their own choice.

Splicing Options for Masonry Constructionby Healy (Masonry Construction, 2007) listed several situations where couplers might be advantageous including:

- For use in heavily reinforced elements where couplers can reduce congestion compared to lap splices.

- For larger diameter reinforcement with long lap splices where the material costs for the couplers compete economically with lap splices and reduce the labor to install.

- As an alternative design using larger reinforcement spaced further apart in low-lift applications.

- Where epoxy reinforcement is specified since lap splices must be lengthened by 50%.

- Retrofit applications, such as vertical expansions. Wedge splices could be cost-effective because they can limit the amount of removals.

In addition, bar sizes whose lap lengths exceed the allowable grout lift height should be serious candidates for using couplers.

As mentioned previously, designers can specify couplers as an option to lap splices. However even if the specifications don’t address couplers, the mason contractor is still permitted to propose using couplers. Should the mason contractor submit couplers in lieu of lap splices, the designer must review the submission and decide whether they are acceptable.

There are numerous types of couplers on the market. Most were developed for concrete construction but also apply for masonry. Some tips for engineers to review a mechanical coupler submission:

- Examine the mechanical properties of the coupler. It must be rated to develop at least 125% of the bar yield stress per TMS 602. Have the couplers been tested and certified by an independent agency?

- Some couplers are threaded and require the reinforcement to be threaded also. The threading might reduce the net area of the reinforcement thereby reducing the specified bar capacity. This might require larger diameter bars to achieve the desired capacity.

- Some couplers use welded connections. Verify that the bars are a weldable grade and are compatible with the couplers.

- If coated bars (epoxy, galvanized, etc.) are used, determine whether the coupler is compatible with the coating.

- Check whether the couplers cause clearance problems with the grout.

- Identify what degree of cleanliness is required of the bars. Will mild rust or oil on the bars affect the connection?

- Determine what special inspection requirements must be included during installation.

Q:Our state has adopted the 2015 IBC so now we have to design storm shelters for some projects. We have an upcoming project with a school in a tornado zone. What are the key issues we need to consider for the masonry design of a tornado shelter?

A: Many architects and engineers are faced with this issue. Unless individual states waive the requirement for storm shelters, we will be seeing many more shelters being constructed.

The design and construction must meet IBC, SECTION 423 STORM SHELTERS and the IBC directly references ICC 500 for the design.

Fortunately, there are many resources available to aid designers. A few include:

- ICC 500-2014, Standard for the Design and Construction of Storm Shelters, STANDARD by International Code Council, 12/01/2014

- FEMA: Risk Management Series (26), 2013.

Design Guide for Improving Critical Facility Safety from Flooding and High Winds, FEMA 543, January 2007.

Safe Rooms for Tornadoes and Hurricanes Guidance for Community and Residential Safe Rooms FEMA P-361, Third Edition / March 2015.

- US Department of Homeland Security: Resilience

- National Institute of Building Sciences and Sustainable Building Industries Council: Whole Building Design Guidelines

- Brick Industry Association (BIA): Technical Notes

- National Concrete Masonry Association (NCMA): Tech Notes

- United States Resiliency Council: http://usrc.org/about-us

- Design seminars from the International Masonry Institute.

The ICC 500 is particularly useful to supplement the IBC. It covers architectural, structural and mechanical issues related to storm shelter design.

A tornado shelter is required to provide refuge for people during an event for 2 hours. The electrical systems, power, fire rating, ventilation air, sanitation facilities, potable water supply, and lighting must all provide a minimum 2 hour rating. Entrances and exits must be accessible.

Shelters can be stand-alone facilities or within an existing facility. The IBC notes “Most storm shelters are safe rooms within a bigger facility. Shelters can be used for other purposes during normal building operation. Examples are gymnasiums and classrooms in a school, and locker rooms and bathrooms in a fire station.”

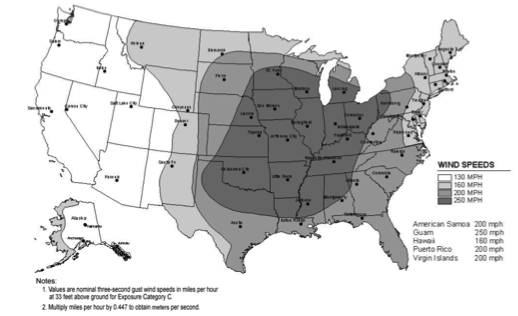

The IBC also states “In areas where the shelter design wind speed for tornados is 250 MPH in accordance with Figure 304.2(1) of ICC 500, all Group E occupancies with an aggregate occupant load of 50 or more shall have a storm shelter constructed in accordance with ICC 500.”

Also in the IBC, “In areas where the shelter design wind speed for tornados in accordance with Figure 304.2(1) of ICC 500 is 250 MPH, 911 call stations, emergency operation centers and fire, rescue, ambulance and police stations shall have a storm shelter constructed in accordance with ICC 500.”

Figure 304.2(1) of ICC 500 is replicated as Commentary IBC Figure 423.3.

Figure 5 – IBC Commentary Figure 423.3, SHELTER DESIGN WIND SPEEDS FOR TORNADOES

Figure 5 – IBC Commentary Figure 423.3, SHELTER DESIGN WIND SPEEDS FOR TORNADOES

From a masonry design perspective, there are several key aspects to consider:

- The MWFRS (walls, roof and floor diaphragms) must resist the design wind pressures based upon the wind speed. The wind will produce a significant uplift on the walls.

- The masonry wall system selected must meet debris impact criteria for tornado shelters from ICC 50. A 15-lb, 2x4 traveling 100 mph must not penetrate the wall or damage the interior surface.

The debris impact criteria applies to all aspects of the building envelope including windows, doors and openings. Testing is required if not already

- ICC 500 states that “Joints, gaps or voids in a shelter envelope that open into the protectedoccupant area similar to masonry control joints, expansion joints, opening protective device shim spaces, air louver blades, grates, grilles, screens or precast panel joints shall be considered openings and shall be protected in accordance with Sections 306.3 and 306.4.”Masonry control joints, masonry or concrete expansion joints, or precast concrete panel joints 3/8-inch (9.5 mm) or less in width are exempted if they are sealed with joint material in accordance with TMS 602 for masonry or ASTM C920 for concrete.

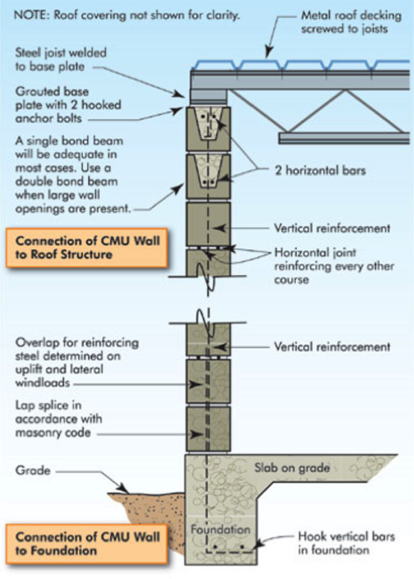

- Wall connections are critical to creating a reliable load path.The structure is only as strong as the weakest link.

As an example, the next figure is taken from FEMA P-361. For masonry, the lap splices used within the walls and to the foundations are key to transferring tension from uplift and flexure. Don’t forget the importance of special inspections.

Figure 6 – Load Path (credit FEMA P-361, Safe Rooms for Tornadoes and Hurricanes)

Figure 6 – Load Path (credit FEMA P-361, Safe Rooms for Tornadoes and Hurricanes)

While non-masonry contractors might be responsible for anchoring floors and roofs to the walls, those connections are essential. Designers need to calculate ail the load transfer between the diaphragms and the walls and detail those connections.

Storm shelters are vital to protecting our children and families. Errors in the design or construction have serious consequences should there be a failure. MCAA recognizes the importance of storm shelters and has created a Storm Shelter credentialing program for its members. When designing masonry storm shelters, consider specifying the work be done by masons who are either MCAA-credentialed or IMI-trained.

Thank you for following this column. Hopefully, we’ll produce more economical designs by sharing information. Remember, by bonding we get stronger!

David is a PE and SE with Biggs Consulting Engineering, Saratoga Springs, NY, USA. He specializes in masonry design, historic preservation, forensic evaluations, and masonry product development.