Brick Veneer: Wall Ties and Adhesion

Words: Jim Tann

Words: Jim Tann, Director of Technical Services, The Belden Brick Company

Featured Image: Anchored Brick Veneer (Photo credit: MILLER+MILLER Architectural Photography)

Other Images: As Noted

Introduction

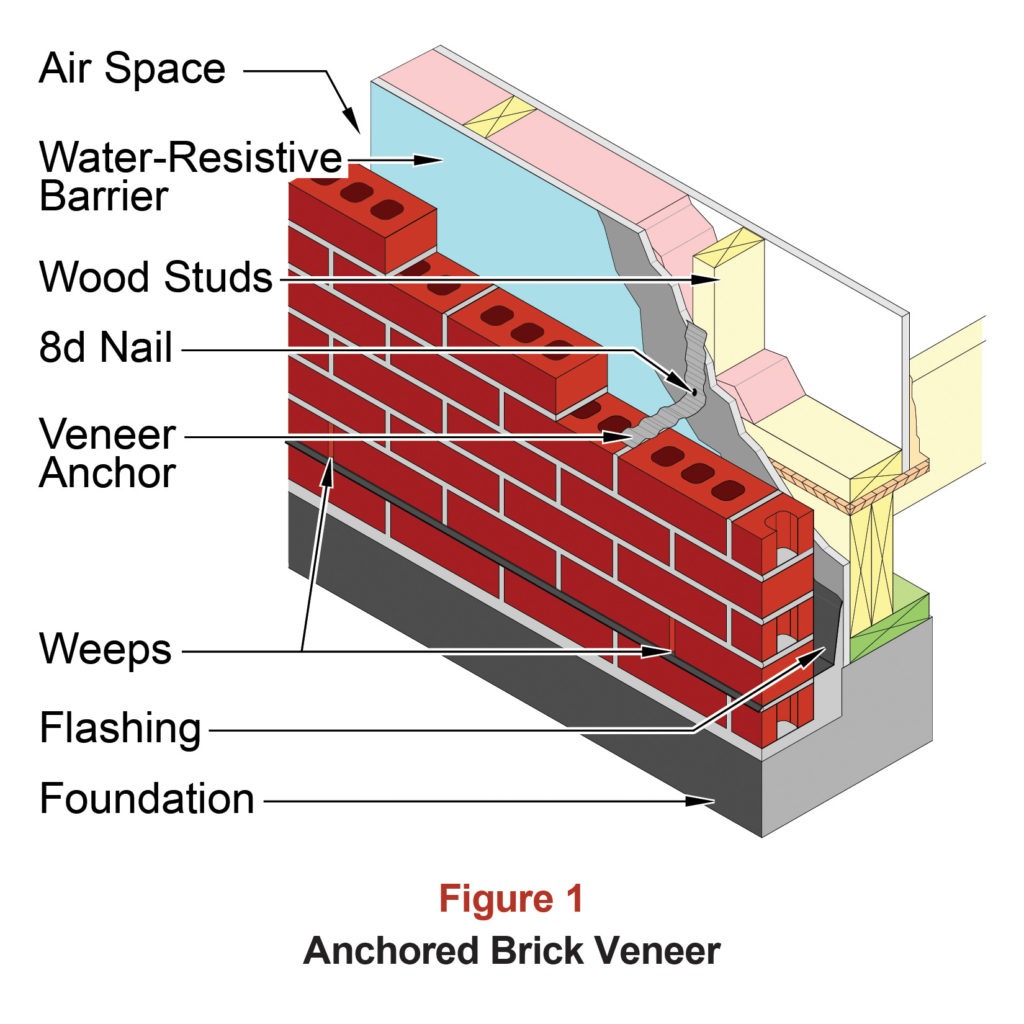

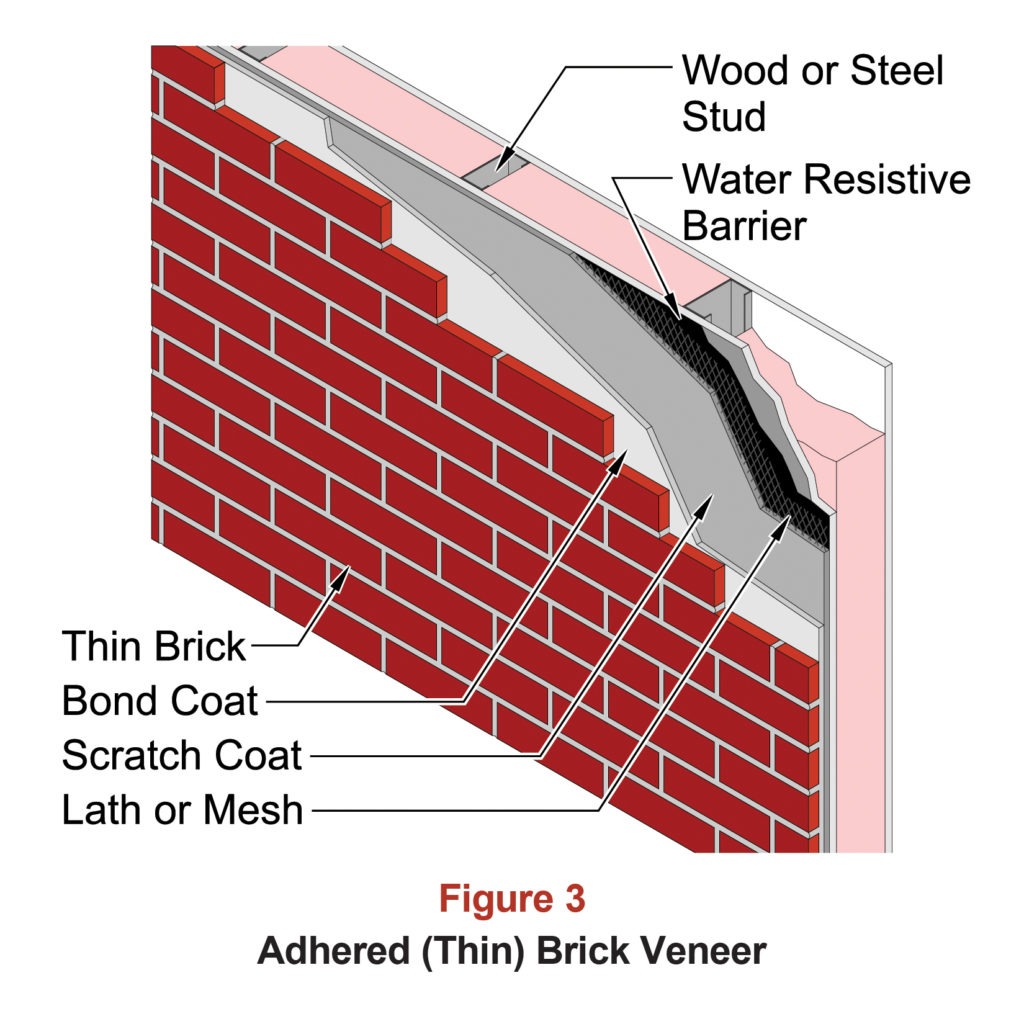

Brick veneer walls can come in various forms depending on the backup system and thickness of the brick veneer units. These walls are either referred to as “anchored veneer” or “adhered veneer,” and they have different code requirements for their design and construction. Anchored veneer utilizes full-depth brick units, whereas adhered veneer utilizes thin brick units.

As the names suggest, anchored veneer relies on the use of metal wall ties to attach (anchor) the veneer to the backup, while adhered veneer in vertical walls relies on a bond coat to attach (adhere) the veneer to its substrate. There are also some hybrid systems for installing thin units to a substrate using proprietary panel systems attached to the substrate and receiving the thin brick units. This article addresses anchored veneer and adhered veneer using a bond coat.

Anchored Brick Veneer

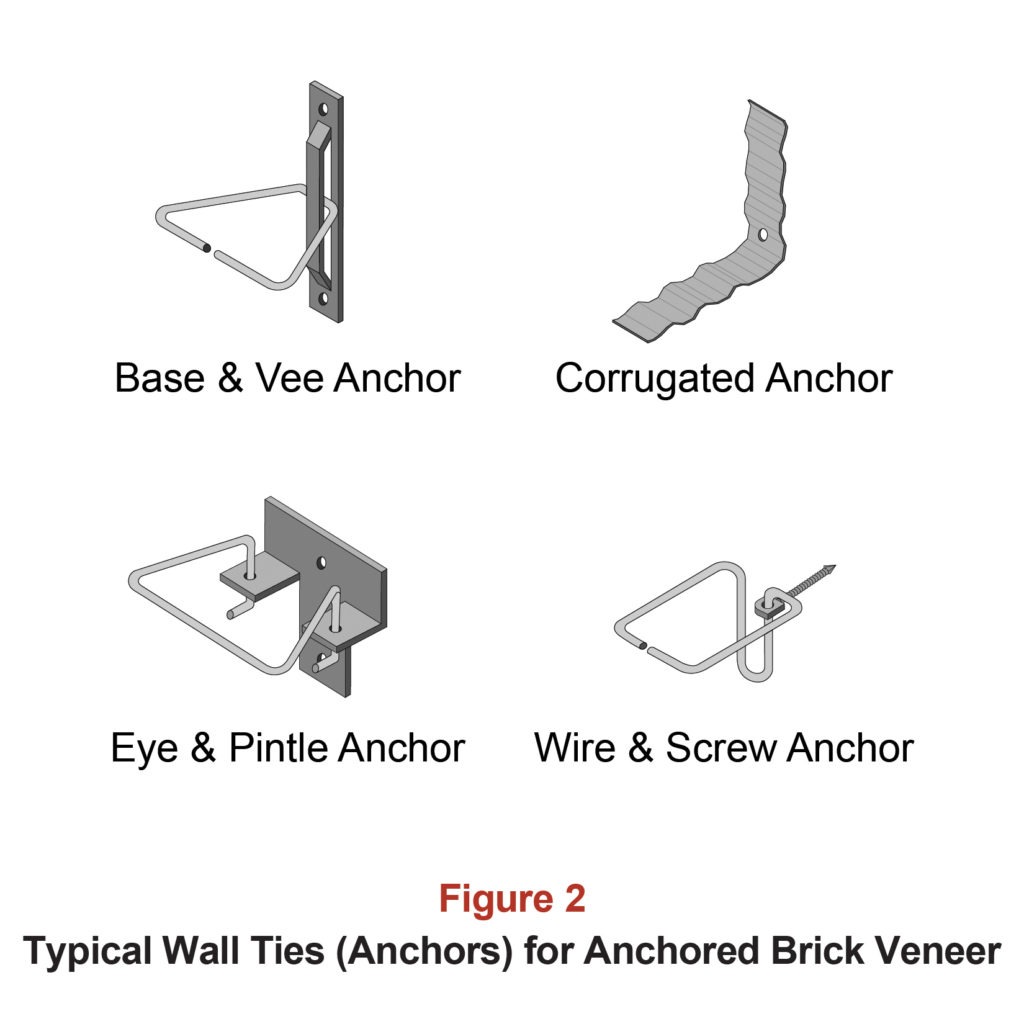

When it comes to anchored brick veneer, wall ties can take several forms, depending on the backup system and load transfer. Typical backup systems are wood studs, metal studs, and concrete masonry units (CMU). With these systems, adjustable wall ties are preferred to accommodate differential movement and allow for coursing variations between the brick and CMU. In the case of brick veneer used over a wood stud backup in residential home construction, corrugated strap ties can be utilized as a variation.

Both the International Residential Code (IRC) and International Building Codes (IBC), in their prescriptive requirements, have limits on the unit thickness (minimum and maximum) and wall tie size and spacing for anchored brick veneer walls. Generally, the brick units are a nominal 3-inch or 4-inch in thickness, and wall ties are provided for every 2 to 2-2/3 square feet of wall area. Additional ties are required at discontinuities, such as window and door openings. These additional ties are to be placed within 1 foot of the discontinuity and within every 3 feet on center around the discontinuity. Decreased tie spacings are required in areas with prevalent seismic activity or high wind.

(Credit: The Brick Industry Association (BIA))

(Credit: The Brick Industry Association (BIA))

Three necessary functions of the wall ties are to provide a connection between the anchored brick veneer and the backup, transfer loads (lateral loads such as wind and seismic) from the anchored brick veneer to the backup and accommodate movement in the wall system. All wall tie types provide these functions; however, some are more efficient than others in their function. As a result, building code has limits on the use of some tie types due to their performance under loading. For efficient performance, the ties should extend across the cavity and be embedded into the anchored brick veneer at least 1-1/2 inches, maintaining a minimum 5/8-inch mortar cover.

(Credit: The Brick Industry Association (BIA))

(Credit: The Brick Industry Association (BIA))

Anchored brick veneer is separated from the backup with a cavity space. This space typically houses continuous insulation and an air space for water drainage. Building codes have traditionally limited the size of the cavity space to a maximum of 4-1/2 inches. However, due to the implementation of energy conservation codes requiring higher insulation levels in exterior walls, the maximum cavity space size has recently been increased to 6-5/8”. The air space in the cavity also has a code-regulated minimum dimension of 1 inch. The ties used for the brick veneer must be capable of performing over the whole cavity dimension. Adjustable ties with a wire size of 3/16 inches or better can be used over these cavities. Corrugated strap ties of a minimum of 22 gage metal can be used with wood stud backup systems. However, these ties are less efficient with large cavities. As such, the building code limits the cavity dimension to 1 inch. Should a wider cavity be necessary or desired, a wire must be used in lieu of the corrugated strap tie, or an engineered design that can demonstrate wall stability with the corrugated tie is necessary.

Adhered Veneer

Thin brick is becoming increasingly popular for use on vertical walls. Thin brick units vary in manufacture and in thickness depending on manufacturer and use. Common thin brick thicknesses are between ½-inch and ¾-inch. Thin brick units can be manufactured as thin units or cut from full units to achieve a thin profile. Flat slab units, 90-degree corner units, and sill cap units are common configurations offered. Nonetheless, thin brick units are true fired clay masonry units, having all the attributes of brick units, but are thinner. The units are non-combustible; however, their thin profile reduces their impact on a fire-rated assembly.

Adhered (Thin) Brick Veneer (Photo credit: Kaminski Studio)

Adhered (Thin) Brick Veneer (Photo credit: Kaminski Studio)

Adhered brick veneer, like anchored brick veneer, has prescriptive requirements in the building code. These are such that the unit size and weight are limited, and the shear strength created by the mortar adhesion of the units to the substrate is a minimum of 50 pounds per square inch, or the tensile strength created by an approved adhesive to the units and the substrate is 50 pounds per square foot.

Adhered brick veneer systems can be a barrier to water penetration or can be designed and built to provide a drainage plane between the bond coat and substrate. In each barrier or drainage system, thin brick units can be adhered with mortar (known as thick set) or thin set adhesives (known as thin set). In thick-set drainage systems, wire mesh is typically used over the drainage plane to assist in the bond to the substrate. In thin-set drainage systems, cement board is placed over the drainage plane and receives the thin brick units with thin-set adhesives. Flashing is utilized over the opening to allow drainage to the exterior, and a weep screed is utilized at the bottom of the adhered brick veneer. Building code requires the thin brick veneer to terminate above the finished grade. Different termination heights above grade exist depending on the actual grade material (soil or paving).

(Credit: The Brick Industry Association (BIA))

(Credit: The Brick Industry Association (BIA))

Accommodating Movement

In both brick veneer systems, anchored and adhered, movement must be accommodated. In most cases, the intent is to accommodate the growth of the brick masonry. However, provisions may also be required to address differential movement between the brick masonry and the supporting structure or adjacent materials. Rules of thumb exist for placement of movement joints in anchored and adhered brick veneer walls. For anchored brick veneer, these include:

- Movement joints (called expansion joints) are to be placed in the brick veneer for the full depth of the brick unit and must be compressible so that they allow the brick to expand under changing moisture and thermal exposure.

- Place vertical expansion joint in long walls not to exceed 25 feet on center, horizontally.

- Place additional vertical expansion joints near building corners (typically on the shorter wall).

- Place additional vertical expansion joints at changes in wall heights.

- Place additional vertical expansion joints at offsets in the wall plane.

- Where anchored brick veneer is supported on relief angles in multi-story construction, place horizontal expansion joints in the veneer under the horizontal leg of the relief angle.

For adhered brick veneer, the rules of thumb include:

- Expansion joints are to be placed in the brick veneer for the full depth of the brick unit and bond coat or thin-set adhesive. They must be compressible.

- Place expansion joints in long wall not to exceed 18 feet on center, horizontal, and vertical.

- Maximum wall area between expansion joints should not exceed 144 square feet or a length-to-height (or height-to-length) ratio of 2-1/2 to 1.

- Place additional vertical expansion joints near building corners (typically on the shorter wall).

- Place additional vertical expansion joints at changes in wall heights.

- Place additional vertical expansion joints at offsets in the wall plane.

- Where movement joints exist in the substrate, align adhered veneer expansion joints with the substrate’s movement joints.

Conclusion

Both anchored brick veneer and adhered brick veneer are viable exterior wall systems that offer all the advantages expected of brick masonry. Using wall ties in brick veneer depends on the specific system and building code requirements. According to the standards, anchored brick veneer requires wall ties, while thick and thin set adhered brick veneer do not need wall ties in vertical walls as they rely on the bond strength of the systems bond coat.