Mind The Gap: How Injection Foam is Changing the Insulation Game

Words: Kevin Cavanaugh, Bob Sullivan I recently stayed overnight in a 120-year-old converted warehouse to hotel in Minneapolis that was built with uninsulated clay brick walls. I was perfectly comfortable as it snowed outside, and I had even turned the hotel room’s heating system off. Those of us in the masonry industry understand well the inherent thermal comfort benefits provided by massive masonry walls. Unfortunately, these benefits are not as easy to measure, nor as easy to write into a simple-to-use, building code inspector friendly, energy code language.

By contrast, on the other hand, easy to use AND easy for building code inspectors to inspect, exterior wall insulation requirements were written into the first national energy codes in 1975 (ASHRAE 90.1 and 90.2). These requirements focused on how much insulation, usually in the form of fiberglass batts or rigid foam plastic boards, needed to be added to exterior walls. These requirements, known as the minimum ‘R-Values’, were listed in the ‘Prescriptive’ section of the code. It was super easy for code inspectors to look at the back of a fiberglass batt and see the R-11 or R-19 printed on it. The insulation industry did a great job lobbying the energy code writers. And they were given a huge helping hand by the then newly created US Department of Energy (DOE).

1977 In, not long after these first national codes were written, the Carter administration created the DOE with mandates to visibly address the OPEC oil embargo, promote energy conservation, control power supplies and develop alternative energy sources. You may recall at that time there was a great fear that energy shortages would be the ‘new normal’. OPEC’s embargo subsequently collapsed on its own, but the DOE was up and running strong.

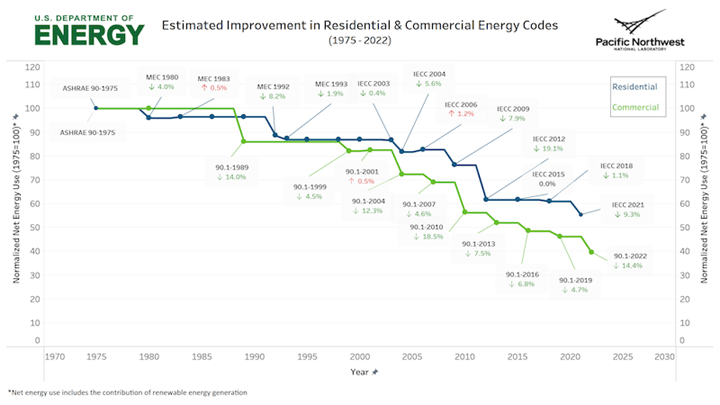

The net effect, at least as far as exterior walls in buildings go, is that ever-increasing levels of wall insulation were and are needed to pass the energy code. This extra insulation, along with improvements in lighting and HVAC systems, have resulted in today’s building using only 40-60% of the energy that would have been needed had these codes not been written and adopted. See Figure 1.

Another effect is that meeting the minimum prescriptive R-Value requirements, not surprisingly, became more and more difficult for single-wythe concrete masonry unit (CMU) walls. As you are aware, single-wythe CMU walls are a workhorse, ‘jack-of-all-trades’ type of building material. They have excellent fire-resistance, fire safety, resiliency, structural, acoustical and aesthetic properties. They are not a food source for molds to feed upon and are termite and vermin-proof. They offer excellent carbon sequestration capabilities per the Concrete Masonry and Hardscape Association’s recent research and MIT’s Concrete Sustainability Hub. (Ref. 1 insert a CMHA graphic or reference to research). Unfortunately, achieving the ‘high’ R-Values, on par with the many super insulated light frame wall systems now available, is a challenge for single-wythe CMU walls.

On the plus side, there are a couple simple energy code compliance options available that are proving to work very well in keeping single-wythe CMU walls viable in even the coldest of climates.

These options are:

- Use COMCheck. Tell architects and your block suppliers to use the more flexible, trade-off compliance path the relies upon DOE’s free COMCheck software.

- Use Injection Foam. Low-cost, easy to use injection foam makes a mason contractor’s task much easier.

Injection foam, because it does not require special, proprietary CMU shapes and fittings that many of the rigid insert insulated CMU systems use, it can speed delivery of any architectural or custom-made CMU to your job site. Injection foam only adds about $1.00 to $1.50 per block, depending on the size of the block and which market you are in, versus the much more costly rigid foam insert systems. Plus, there is no need for block plants to buy or rent the special molds needed to make the proprietary system CMU. Injection foam works equally well in single-wythe or cavity walls. This article focuses on single-wythe CMU walls. (Insert Photo 1 here – An injection foamed CMU).

Injection foam, aka by its chemical name ‘aminoplast masonry foam’ is ideally suited for insulating exterior CMU walls and as well for acoustically ‘insulating’ interior CMU walls, like those found in the locker rooms of the Milwaukee Bucks Fiserv Forum basketball arena. Unlike polyurethane and polyisocyanurate foams, aminoplast injection foams are not petroleum based. When injected via holes drilled into the face shells of CMU, the non-expanding injection foam flows under modest pressure and completely fills every nook, cranny and hollow core within CMU walls.

Two recent changes to ASTM C90 greatly increased the R-Values of CMU insulated with injection foam.

- The first change, adopted in 2011, allows block producers to make block with fewer and/or smaller cross webs, which significantly reduces the web’s cross-sectional area. This, in turn, reduces the energy loss through the cross webs, which increases the block’s R-Value.

- The second change, adopted in 2014, increased the minimum compressive strength requirements of an individual CMU from 1900 psi to 2000 psi. While a 100 psi increase to 2000 psi may seem small, the design strength, known as f’m (F prime M), increased from 1500 psi to 2000 psi. This 25% increase is gigantic in the structural engineering world. The design strength includes the effects of mortar, grout, weather conditions when installed and workmanship. Typically, rather than build a two-block high prism and crush it in a compression testing machine to determine the f’m, our industry has relied upon simple tables that relate individual CMU strength (which is well known and readily shared by block producers) to f’m. Historically, a 1900 psi CMU translated into only a 1500 psi f’m. Today, due to better manufacturing, better materials and better workmanship, a 2000 psi CMU translates into a 2000 psi f’m design strength. The practical net effect of this is that less vertical rebar and grout is needed to get the same structural performance. Where rebar at 32” and 48” on center were historically typical, today 64” and 72” on center spacing is starting to become typical. Time will tell if it becomes the new normal. Less steel and rebar are good for your bottom line and favorably impact CO2 reduction efforts. And, best of all, they allow for more portions of the wall to be insulated, which leads to even higher CMU wall R-values and easier energy code compliance.

There is one more option that will further increase R-Values of any CMU wall and that is to use lightweight block. Lightweight CMU concrete has about 5X more heat flow resistance per inch of concrete than its normal weight cousin, aka heavyweight CMU that masons do not want to install!

Aminoplast injection foam is available across the US from a half dozen suppliers who market through company-owned contracting operations or authorized independent contract installers who are equipped, trained, supplied and technically supported by their respective foam supplier. These authorized installers bid their work to, and contract their work with, either the GC or the masonry contractor.

Additionally, today’s 5th generation advanced aminoplast foam insulation manufacturers rely on 100% ‘dry resin’ technology to produce their resins. As a result, one ‘dry resin’ foam manufacturer is able to offer injection foam that fully complies with California air quality and LEED v 4.1 emissions criteria.

In closing, as we see the proliferation of competitive wall systems, let’s make sure to remember that

single-wythe, lightweight CMU buildings insulated with ‘dry-resin’ aminoplast injection foams are, for mason contractors, easy, fast and low cost to build. Even better, they are low cost to operate and energy code compliant throughout the Lower 48 States making them incredibly attractive to owners and developers of all building types: especially big-box retail and schools. No competing wall construction method is as resilient, sustainable, fire resistant or as easy to maintain as injection foam insulated single-wythe lightweight block walls.

If you would like to learn more, please feel free to reach out to the authors via email or phone.

------------------------------- Related Info below / Bios / Figures & Photos -------------------------------

Author Information:

Bob Sullivan is cfIFOAM’s Technical Director. After spending many years in the frame-wall insulation industry as a sales manager and technical expert his eyes were opened to the masonry industry. For the last 16 years he has been actively educating architects, mason contractors and block manufacturer sales reps on the benefits of using low-cost, easy to install, injection foam insulation to create energy code compliant CMU walls. He can be reached at: Bob4Foam@msn.com or by phone at 434.546.3632.

Kevin Cavanaugh currently chairs ACI/TMS Joint Committee 122 on Energy Efficiency of Concrete and Masonry Systems that is charged with developing masonry friendly national energy code standards, NCMA’s CMU Technical Committee and the Expanded Shale, Clay and Slate Institute’s Masonry Committee. He has worked for large, multi-national and small, family-owned CMU manufacturing companies and several lightweight aggregate producers. He enjoys the people in the concrete and masonry industries and educating owners, architects, mason contractors and masonry suppliers on lightweight concrete masonry’s many benefits. He can be reached at: Kevin.Cavanaugh@Arcosa.com or by phone at 414.559.6434.