Cleaning and Caring For Clay Brick vs. CMU

Words: Darcy Boyle, Jake Boyer

Words: Darcy Boyle, Media and Communications Director

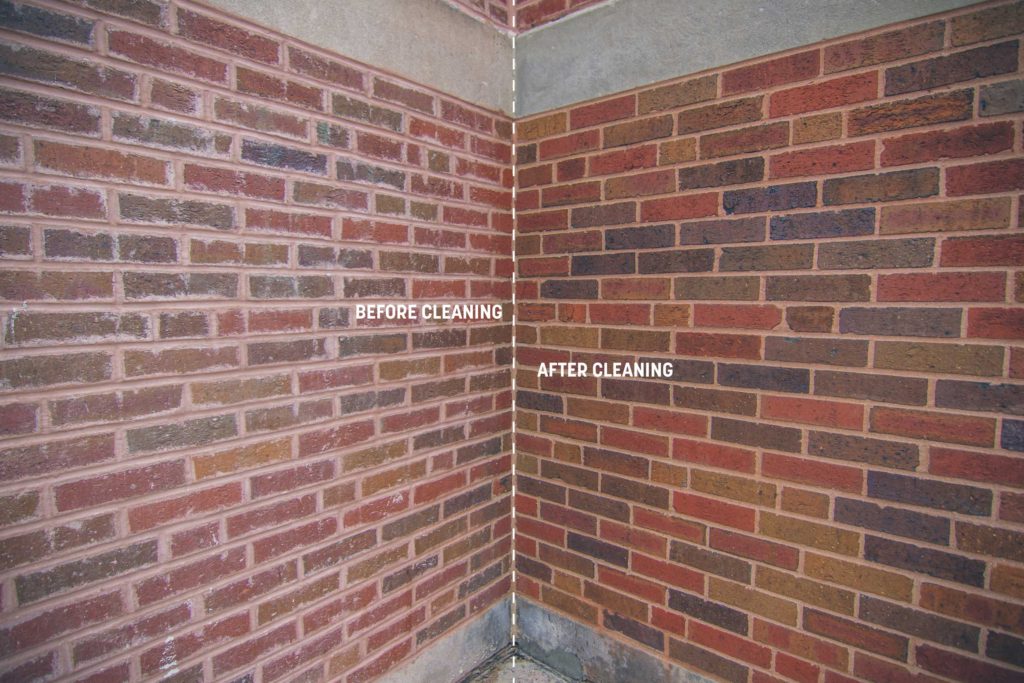

Photos Courtesy of PROSOCO

While concrete masonry units (also known as CMU) and clay brick are two of the most commonly used masonry materials in construction, their chemical and structural makeup are not the same – meaning your cleaning and care strategies for each one should differ accordingly.

Even within the general categories of “brick” or “CMU,” there are many combinations of ingredients that contribute to their appearance and performance. For starters, the primary ingredient in many bricks is clay, where CMU is made of concrete. Traditional clay brick tends not to be as sensitive in the presence of many common masonry cleaners, while concrete, by its nature, is acid-soluble. Both are incredibly resilient materials and superior to many other common building materials. Still, you need to be aware of the chemical composition of each before identifying the appropriate cleaner for your project, according to Jake Boyer, head of PROSOCO’s Clean and Protect Group.

The acid sensitivity of many concrete materials isn’t necessarily a bad thing. It can work to your advantage in cases where you want to make the surface color of CMU appear more uniform over the entirety of the wall – it just means that you need to select the appropriate product, dilution, and application method for your specific substrates to ensure your desired results. Like most things in life, one size does not, and should not, fit all when it comes to your choice of cleaners and protective treatments for these two materials.

Let’s start with bricks.

Even within the general category of brick, there’s variation. Color and porosity are two identifying factors that will help direct you to the right product for cleaning and care. The subtle nuances of the other ingredients in the brick all impact the chemical reaction that takes place during the cleaning process. While you may use the same product on a few different types of brick, other factors need to be considered, like dilution and dwell time. Other types of brick that may appear the same may require a different cleaner entirely to ensure you get the appearance you’re going for. That’s why testing on site is so important for every job.

“Vana Trol tends to be a pretty safe starting point for many types of clay brick and is more buffered than most other traditional masonry cleaners,” he says. “On the other hand, if you have a standard red clay brick without additional pigments and minerals, you may be able to get the job done a little quicker with a product like 600 without risk of secondary staining.”

With Vana Trol, “buffered” means that it contains additional wetting agents to keep the material wet on the wall longer, as well as other surfactants and ingredients that help suspend the stains away from the surface and make your brick easier to rinse.

When it comes to applying a protective treatment to brick, porosity matters, in general, brick tends to be less porous than most CMU, so Boyer is more likely to recommend testing a product like Siloxane PD or SL100, products that are geared towards penetrating dense masonry surfaces, like most clay brick.

Let’s talk block

Wide view at modern wall made ouf of concrete blocks

Wide view at modern wall made ouf of concrete blocks

Again, there’s no “one size fits all” solution for CMU either – whether it’s standard gray structural units, colored, burnished, or split-face units, and even the color of your mortar all are big considerations for choosing the best cleaner.

For example, if he’s dealing with burnished pigmented CMU, Boyer’s first recommendation is typically Light Duty Concrete Cleaner.

“It contains no hydrochloric acid, and it’s much milder overall than a lot of other products. It’s going to allow you to get the surface clean without concern for the sheen on the burnished face and the widest margin for error.”

To protect CMU with a water and/or graffiti repellent, the general rule of thumb to remember is that CMU tends to be more porous than clay brick. Boyer stresses that this is not absolute, and many products can be effective on both – but many times, CMU requires a protective treatment containing a larger molecular structure to protect the more porous surface appropriately. To protect CMU, he’s more likely to suggest contractors test with a silane-siloxane blend like Siloxane WB Concentrate or a silicone formula like one found in PROSOCO’s Blok-Guard & Graffiti Control family of products.

All differences aside

Knowing the differences between CMU and clay brick that require special considerations, let’s now look at what they have in common. Their similarities are found in the core chemistry and techniques necessary to clean and protect these surfaces.

#1 – Start low and slow.

Boyer swears by a simple rule that’s endorsed by every industry authority and organization out there – do not apply acids at high pressures, and always start with the mildest dilution and application method that you can and work toward more aggressive as necessary. You can always add to it to get more aggressive if needed, but there’s no going backward.

#2 – The more water, the better

Boyer says that masonry cleaning, whether CMU or brick, is not the time or place to skimp on water.

“I’m all for saving water, and we go to great lengths to promote healthier materials and reduce consumption, but cleaning masonry is not the place to try and save water,” he says. “You’re going to wind up using a hell of a lot more when you have to reclean the building because you didn’t adequately pre-wet or rinse it and end up with residual staining.”

One notorious result of too little water used in masonry cleaning is white scum.

“White scum is partially dissolved mortar that is redeposited back onto the surface, and often confused for efflorescence, but much more resistant to cleaning,” Boyer says. “As a result of it being only partially dissolved, combined with the water that was used in rinsing, it allows that material to further hydrate and finish curing. Full hydration is a good thing in the joints but bad in the form of white scum on the surface.”

“Especially when paired with inadequate pre-wetting, inadequate rinsing can also perpetuate efflorescence and lime run, and even negatively impact the application of a protective treatment by leaving the pH of the wall too low. Often, this results in a whitish haze, which is, again often confused for efflorescence but is more difficult to remove.”

#3 – Pre-wetting is critical

Pre-wetting the wall is every bit as important as rinsing, and Boyer frequently uses this analogy to illustrate the reason why: Imagine a sponge completely saturated with water. If you were to take a glass of red wine and pour it over the sponge, it wouldn’t absorb into the sponge very deeply because the sponge’s pores are already full of water. Now consider pouring that wine onto a dry sponge – the wine would thoroughly soak into the sponge due to its dry condition and ability to absorb, making it much more difficult to rinse. Especially if allowed to dry on the sponge first.

The same is true with a masonry surface. Pre-wetting fills the pores so that when you apply an acidic cleaner, the acid cannot be absorbed deep into the pores. PROSOCO’s new masonry cleaners are lighter than water and will not displace the water already occupying the space within the masonry. That keeps the cleaning power concentrated at the surface where it belongs.

“You only want the cleaner working at the surface,” Boyer says. “There’s no benefit to the cleaner penetrating beyond the visible surface because the goal is only to clean what you can see. Additionally, keeping it out on the surface makes rinsing much easier.”

#4 – Don’t be afraid of the word “acid.”

Boyer wishes “acid” wasn’t a four-letter word – because it’s a naturally occurring and necessary substance when it comes to so many things in life, including masonry cleaning. You can blame the laws of chemistry for that.

“To dissolve mortar smears or any other alkaline material, according to those laws of chemistry, you have to have something acidic,” Boyer says. “Acid and alkaline are kind of like hot and cold, with warm being neutral. If you have hot water and want to get too warm, you add cold. If you have cold water and want to get too warm, you add hot. It is that simple. If it’s dissolving alkaline mortar smears, it’s acidic, period. Just check the pH on the SDS if you have any questions about the acidity. There’s nothing else out there that will do that, despite some creative language found in many marketing materials.”

For customized solutions for cleaning and protecting CMU, brick or any other kind of masonry, contact PROSOCO at prosoco.com or 1-800-255-4255.