University Project Shows Rainscreen Success with Granite

Words: Greg Lepore, Jason Kron, Michael Grimm, Duane Krueger

Words: Jason Kron

Photos courtesy of Michael Grimm Photography

While open joint, or rainscreen, cladding systems have become an industry standard, many design teams overlook the opportunity of incorporating natural stone into the plan. These open joint systems gained popularity in recent years for their benefits to a building’s lifetime performance, with terracotta and metal comprising the most common selections for the cladding material. However, when an upscale finish or greater design freedom is desired, granite offers an ideal solution.

Stone can provide great performance with a rainscreen design, yet design teams often have many questions about incorporating them. Is granite too heavy for a rainscreen system? What kind of anchoring details are required? Will the stone panels remain secure? Can I be confident that a rainscreen with granite will remain low maintenance for years to come?

With today’s rainscreen cladding systems designed specifically to incorporate natural stone, granite can provide a long-lasting, beautiful option for building designs. By understanding the details of the systems, a team can confidently specify granite for a rainscreen.

Understanding Anchoring

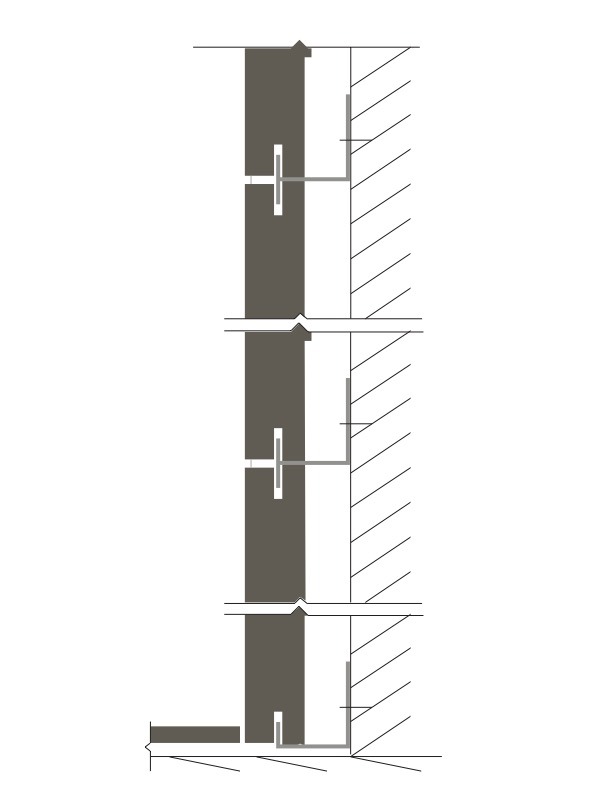

When specifying stone for a rainscreen system, it’s important to understand the anchoring systems that work best with the building’s design. In a traditional cladding system for stone, anchors connect each cladding piece, and a 1- to 2-inch (2.54- to 5.08-cm) air gap lies between the cladding and the building.

When moisture builds up in the air gap, gravity pulls it down to the base course of the building, where channels weep the moisture toward the outside.

Rainscreen systems keep buildings moisture-free with open joints that create a breathing exterior skin for the building. Air transfers back and forth, eliminating the buildup of moisture or condensation between the cladding and the building.

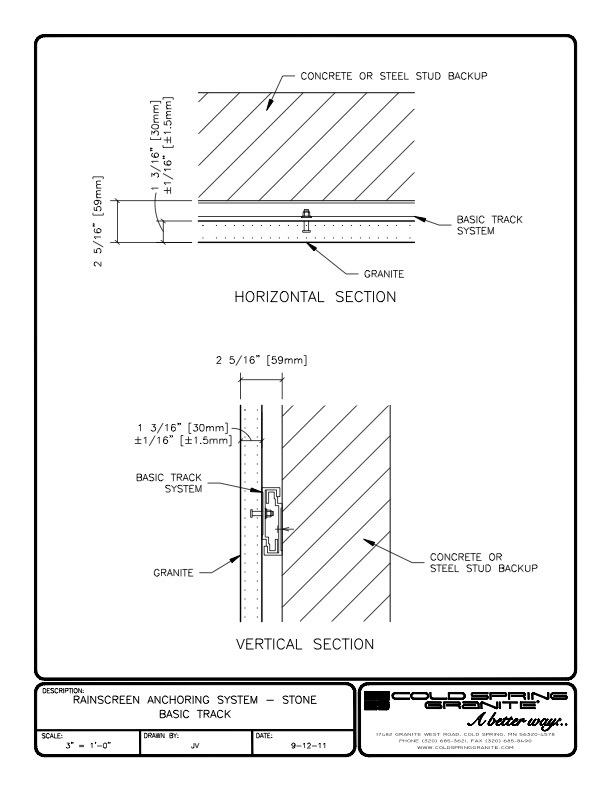

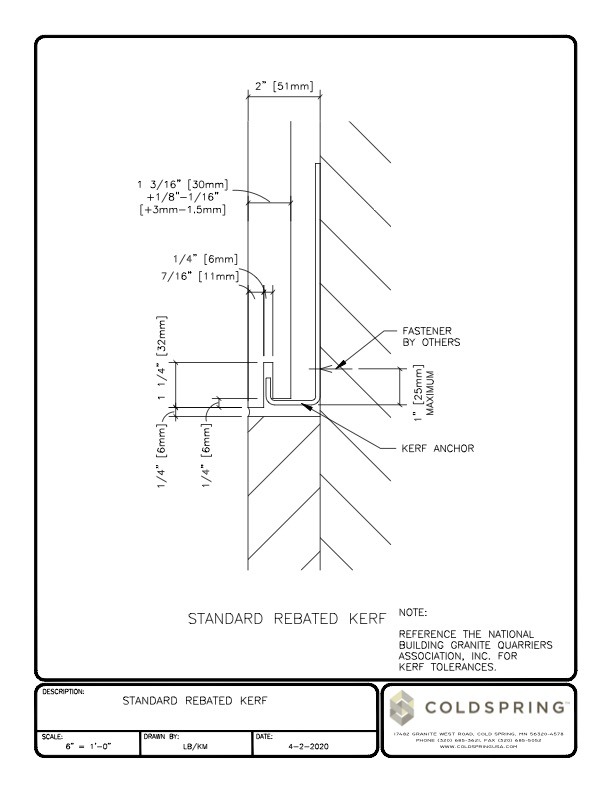

One of the design team’s primary concerns with anchors for a rainscreen system is keeping them unexposed. The two most common hanging methods include a track-type system and a rebated kerf design to provide the seamless appearance of unexposed anchors with the strength required to hold granite in place in a rainscreen securely.

The track-type system is perhaps the most widely used way of securing stone to a rainscreen system. A track system combines wall anchors to support kerf-cut thin stone and works essentially as a clip configuration that allows the stone to be attached to an aluminum or stainless-steel rail with a Type 31 anchor.

Functioning like a tension anchor, the anchor in a track system remains hidden behind the stone and doesn’t sit in the kerf at the edge of the piece. The stone fabricator creates slots in the back of the stone pieces for the anchors to fit into. This allows joints to remain open and air to be transferred without visible anchors.

The second most common method of rainscreen anchoring is a rebated kerf design. An L-shaped cut is made at the edge of each stone piece to conceal the anchor in this design.

The following case study provides an excellent example of a rainscreen system incorporating natural stone for a beautiful outcome.

Temple University Library

Located in Philadelphia at Temple University, Charles Library is one of the country’s most modern and significant new library constructions in recent history. Its design demonstrates the creative possibilities with granite and rainscreen systems and fulfills the architect’s intent to spur imagination and inspire excellence.

Key to the building’s striking design is more than 37,000 square feet (3,437 square meters) of Mesabi black granite from Coldspring, specified for exterior cladding, windowsills, soffits, coping, and a green roof wall façade.

Coldspring worked hand-in-hand with the architecture firm Snohetta of New York to meet the design intent. Before the project started to view numerous mockups of the material and finish options, the architect visited Coldspring’s Mesabi Black quarry in Babbitt, Minn. Throughout the process, close collaboration between Coldspring and the design team ensured the material’s natural characteristics and the color range associated with its various finish options were understood.

Vertical sections of the granite in a split-face finish clad the library’s solid base and coordinate with the existing campus landscape. A total of more than 30,000 square feet (2,787 square meters) of granite pieces – each featuring rustications or reveals – was successfully produced with manufacturing skill and quality.

“To keep the costs of the rusticated pieces within the owner’s budget, we evaluated our processes from the outset to develop production efficiencies,” says Duane Krueger, Regional Sales Manager for Coldspring.

The stone’s installation on a sealant-less, caulk-less rainscreen system allows for water drainage and evaporation, preventing water from penetrating the facility’s interior while lowering the risk of wall rot.

Each long, slender granite piece for the building’s cladding measures approximately 6 inches wide, 4 feet long, and 2.25 inches deep, presenting a challenging installation for the contractor, Dan LePore & Sons Co. of Conshohocken, Pa. Because of the stones’ small size, they rely on two points of attachment rather than the typical four.

Dan LePore & Sons team laid out the rainscreen’s extruded, anodized aluminum grid system at their shop before delivering it to the site. Each aluminum rail measures 30 feet long.

“Plates mounted on the back of the stone engaged with the horizontal rails of the grid system to form the mounting system,” says Greg LePore of Dan LePore & Sons. “Our skilled installation team then hung each piece along the building’s complex arcs and curves.”

Mesabi Black granite also provides a key design element for the building’s green roof, adorning the façade and coping. The dimensional, 2- by 2-foot granite blocks provided challenging rigging, logistics, and installation at the building’s parapet.

The skilled, well-coordinated team accomplished a beautiful outcome for a challenging design at every project stage. Today, Charles Library is a centerpiece of Temple University and Philadelphia, where its inspiring design promotes learning, innovation, and community.

Collaboration Is Key

The key to a rainscreen project with granite is an early collaboration among all project team members. When stone is considered for a rainscreen cladding system, contact your stone supplier in the conception phase. Working closely with suppliers from the onset of the project will ensure success in realizing the project’s design goals – and the beauty and permanence of stone can be successfully incorporated into the rainscreen system.