Marvelous Masonry - Celebrating Masonry’s Heritage

Words: David Biggs

Words: David Biggs, PE, SE

Photos: David Biggs unless otherwise noted

In previous articles, we’ve visited marvelous masonry in Egypt, Turkey, Iraq, Peru, and the Czech Republic. Check out past issues if you missed any of these! Now we turn to North America for more examples of Marvelous Masonry. While the masonry structures of North America don’t approach the age of the many sites we’ve seen overseas, there are many exquisite examples of quality masonry design and construction.

The technology to construct these structures in North America was primarily derived from European influences brought by the many immigrants that settled the New World. Beginning in the 1880s, differences between North America and European construction practices started to develop. That divergence continues today with a variety of materials and methods.

There were numerous monumental, marvelous masonry buildings constructed in the 18th and 19th centuries. This issue of Marvelous Masonry features the New York State Education Building in Albany, New York, and a National Historic Place in the United States.

Background

The area that was to become Albany New York was first settled by the Dutch in 1614. It was a pivotal location during the American Revolution and later became the state capital in 1797. Today, there are 68 properties listed on the National Register of Historic Places in Albany.

The New York State Education Building was constructed from 1908 to 1912. It was the first government building in the United States dedicated to the administration of education.

Figure 1 - New York State Education Building viewed from the southeast

Figure 1 - New York State Education Building viewed from the southeast

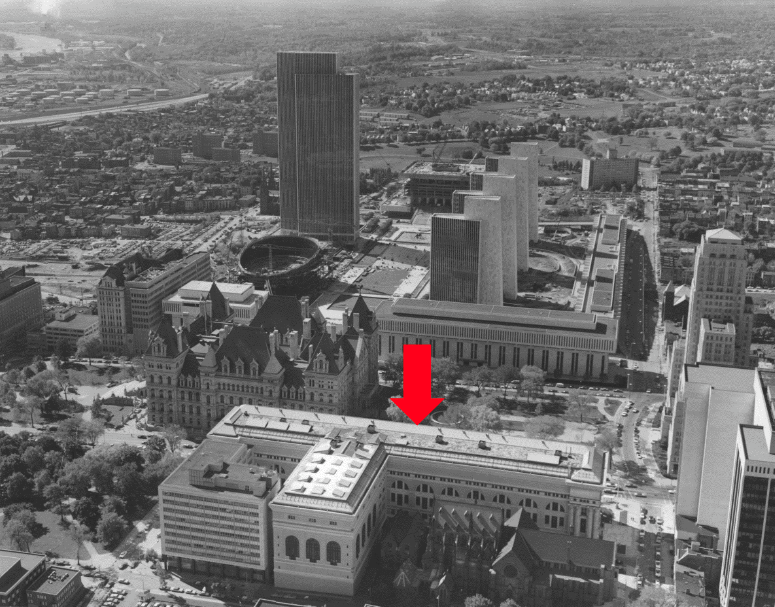

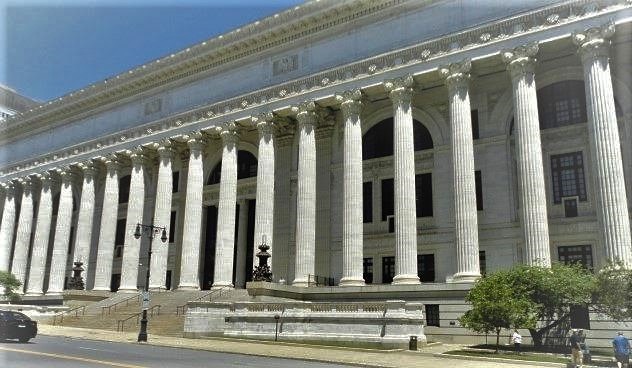

(Historical 1912 Photograph Credit: New York State Education Department)Figure 1 shows the 590-foot long south façade of the Education Building; overall the building is T-shaped (arrow, Figure 2). The south façade forms the top of the T and the south façade has a colonnade of 36 Corinthian columns. Each column is 90 feet tall. The colonnade is the longest continuous one in the United States and one of the world’s longest.

Figure 2 – Aerial View from North

Figure 2 – Aerial View from North

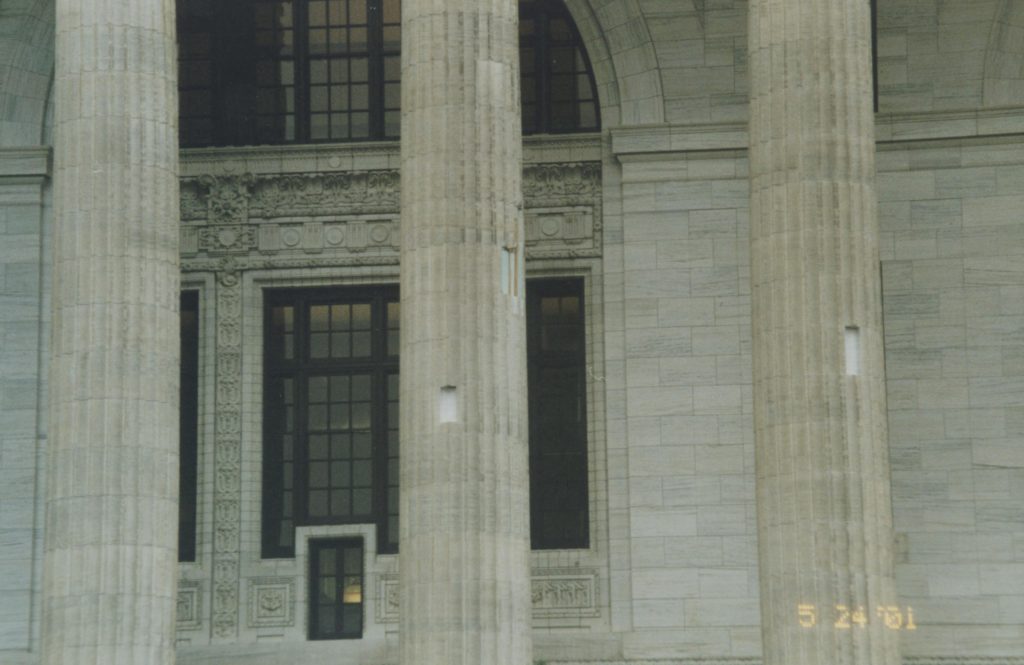

(Credit: New York State Education Department)The building is primarily steel framed. The colonnade columns have internal steel framing encased in brick and faced with Vermont Danby marble to form a 6 ½ ft. diameter at the base. The Corinthian capitals and tablature ornamentation are faced with terra-cotta.

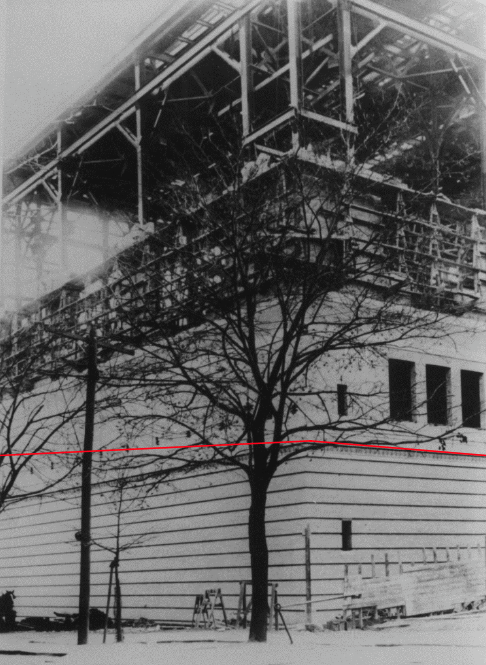

Figure 3 shows the framing of the columns and the entablature at the southeast corner of Figure 1. The foundation walls are visible before the site was regraded (see red lines for the approximate finished grade).

Figure 3 - New York State Education Building southeast corner

Figure 3 - New York State Education Building southeast corner

(Historical Photograph Credit: New York State Education Department)The building’s interior is magnificently detailed as well. There is a 90-foot Rotunda (Figure 4) that has Beaux-Arts influences. Throughout the interior, you’ll find marble columns, Indiana limestone features, and 50-foot high Gustavino vaulted ceilings in the Reading Room. All examples of marvelous masonry.

Figure 4 – Rotunda

Figure 4 – Rotunda

(Credit: New York State Education Department)The architects, Palmer & Hornbostel, were from New York City and quite renowned for the day. Both were Columbia University graduates. Henry Hornbostel also studied at the Ecole des Beaux Arts in Paris, France which greatly influenced his work.

Palmer & Hornbostel were responsible for college campuses at Carnegie Mellon in Pittsburgh and Emory University in Atlanta. In 1910 alone they had four major city halls under design and construction. The firm also was the architect for major New York City bridges including Williamsburg (1905), Queensboro (1905), and Hells Gate railroad bridge (1917).

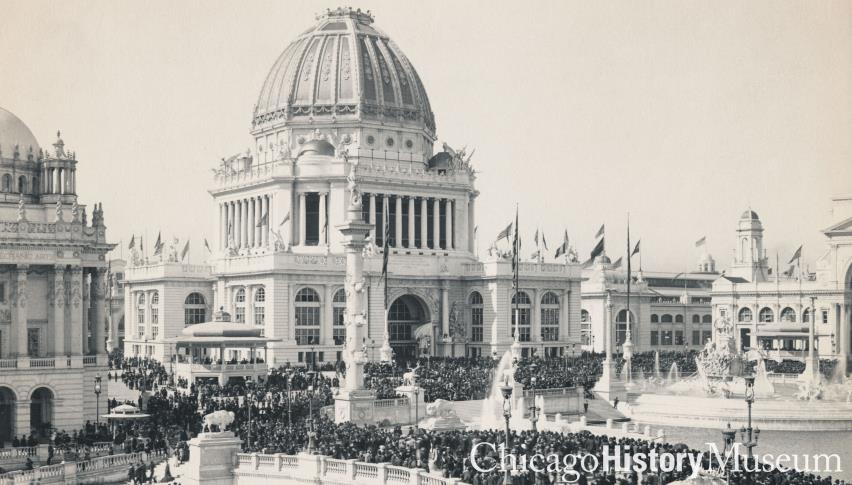

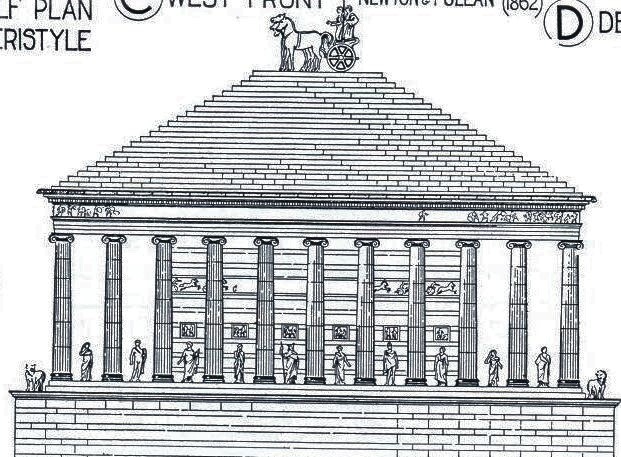

Looking to distinguish the Education Building from other government buildings, the architect reportedly took inspiration from the Neoclassical Style of the 1893 World’s Columbian Exposition (World’s Fair) in Chicago (Figure 5) and the proposed reconstitutions of the Tomb of Mausolus (c. 350 BC) in Halicarnassus which is in Bodrum in modern-day Turkey (Figure 6).

Figure 5 – Administration Building, 1893

Figure 5 – Administration Building, 1893

(Historical 1893 Photograph Credit: Chicago History Museum)Figure 6 shows one of several proposals that were made to reconstruct the tomb but which were not implemented.

Figure 6 – Reconstitution by Newton and Pullan (1862)

Figure 6 – Reconstitution by Newton and Pullan (1862)

(Credit: Sir Banister Fletcher's a history of architecture)Palmer and Hornbostel won the design commission in competition with 62 other firms. Their proposed colonnade was the feature that the judges preferred and secured them the design contract.

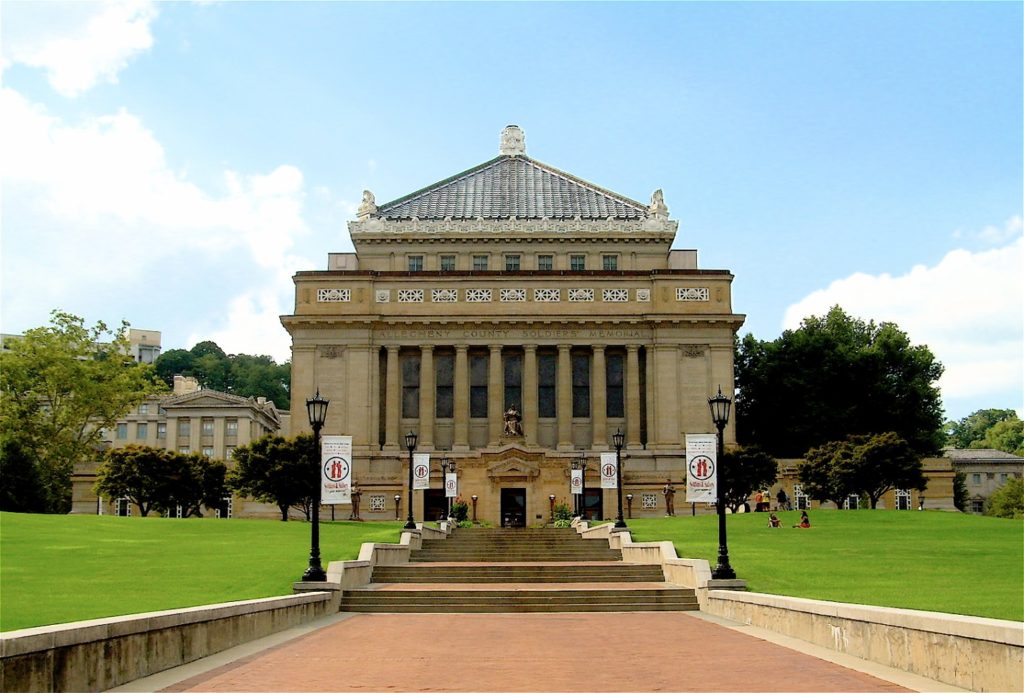

The colonnade is certainly a signature feature of the Education building. They used the concept again at the Soldiers and Sailors Memorial (1909-1910, Figure 7) in Pittsburgh and for a library at Emory University that was never constructed.

Figure 7 – Soldiers and Sailors Memorial, Pittsburgh

Figure 7 – Soldiers and Sailors Memorial, Pittsburgh

(Credit: Willjay at English Wikipedia)The State Education Building underwent multi-year interior renovations to accommodate spatial programming changes starting in 1983 and 1995. In 2001, the State of New York decided to restore the exterior. The task was to clean the façade and repair localized stone damage. Environmental conditions from automobile emissions and wind-blown emissions from a nearby coal-burning plant had darkened the stone. State officials wanted to brighten the facade and restore some luster to the building.

Cleaning

Historical records indicated cleaning campaigns before 2001 included sand-blasting the marble columns. This abrasive cleaning left the surface etched and more prone to collecting rain and dirt. In 2001, cleaning options were evaluated using sample areas; low-pressure wash with a mild cleaner was selected.

Figure 8 shows the colonnade cleaning from 125-foot lifts. The before and after-effects of the column cleaning are obvious.

The arcade was scaffolded to access the walls and ceiling (Figures 9 and 10).

Figure 8 – Colonnade cleaning of the south elevation

Figure 8 – Colonnade cleaning of the south elevation Figure 9 – Arcade scaffolding

Figure 9 – Arcade scaffolding Figure 10 – Arcade cleaning

Figure 10 – Arcade cleaningAfter cleaning, the marvelous masonry can truly be appreciated. Figure 11 shows the before and after of a terra-cotta ceiling ornament of the arcade. The details look like new with little deterioration.

Figure 11a – Before cleaning Figure 11b - After cleaning

Figure 11a – Before cleaning Figure 11b - After cleaning

Figure 12 shows the intricate terra-cotta work of one of the column capitals and some of the entablature. The existing wire bird-proofing was not effective; it was replaced by netting at the column tops.

Figure 12 – Intricate column capital and entablature

Figure 12 – Intricate column capital and entablatureThe original architects were adamant the building needed a very tall entablature above the columns. A narrow one would not be as monumental. Figure 13 highlights the cleaned entablature.

Figure 13 – Entablature above columns

Figure 13 – Entablature above columnsCleaning the building had the most pronounced effect on the appearance. Figure 14 shows the completed cleaning glistening in the sun in 2002.

Figure 14 – Cleaning completed 2002

Figure 14 – Cleaning completed 2002The previous cleaning was completed in the 1970s. To compare the performance, Figure 15 shows the building in 2020. Because there is no longer a coal-burning plant nearby and auto emissions have been greatly reduced since the 1970s, it was hoped in 2001 that the building cleaning would last at least 20 years. Because the marble columns were etched from previous cleanings, only time would tell if the columns would become dirty again at an accelerated rate.

Figure 15 – Building in 2020

Figure 15 – Building in 2020Based on the 2020 observations, the 2001 cleaning has been extremely successful. The columns still shine in the sunlight. There is only some staining observed at some of the window sills of the arcade due to wind-driven rain runoff.

Repairs

As previously mentioned the marvelous masonry of the Education Building did require localized repairs in 2001. These included: caulking window frames, repairing wood frames, repointing mortar, repairing cracked marble, replacing broken marble with Dutchmen, repairing broken terra-cotta, and changing the bird-proofing.

Bird-proofing is often a misnomer; we often can do no more than discourage the birds until they outwit us again. The most effective bird-proofing used has been to retain a falconer to fly his bird around the site periodically to dissuade the return of the birds.

The mortar and marble repairs followed the cleaning operation to obtain a correct color match for the repairs and repointing mortar. Repointing was performed on open joints on a spot basis throughout the façade as seen in Figures 16 and 17.

Figure 16 – Ornamental repointing before mortar cured Figure 17 – Column repointing

Figure 16 – Ornamental repointing before mortar cured Figure 17 – Column repointing

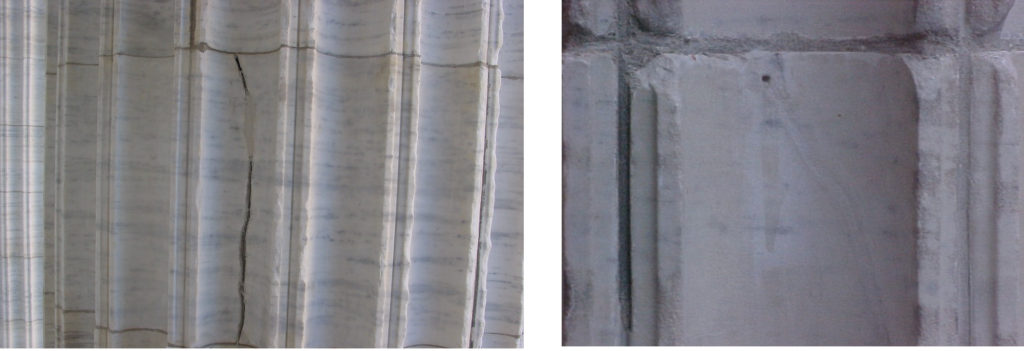

The stone repairs of the columns were more exacting. Figure 18 shows the columns are made from fluted marble courses approximately 31 inches tall. There are four fluted sections to create the circumference of each course. The head joints of the fluted sections are staggered from one course to the next.

Figure 18 – Fluted sections of marble columns

Figure 18 – Fluted sections of marble columnsFigure 19a shows a crack in one of the column sections that has been routed. Figure 19b shows an enlarged view of the top of the crack where the crack has been surface sealed and then epoxy injected. These repairs were used to avoid replacing large sections of the marble.

Figure 19a – Crack in column Figure 19b – Crack repaired

Figure 19a – Crack in column Figure 19b – Crack repaired

There were numerous spots where an injection was not a viable solution. For these full fluted sections, they were replaced or partial sections (Dutchmen) were used. Figure 20 shows one damaged area. Figure 21 shows the broken stone removed.

Figure 20 – Damaged marble Figure 21 – Damaged marble removed

Figure 20 – Damaged marble Figure 21 – Damaged marble removed

Fortunately, the source of the original marble stone was found in Vermont. For the replacement stone, patterns were made by the mason and fabricated at the quarry workshop of Gawet Marble and Granite. Figure 22 shows two of the many patterns created.

Figure 22 – Replacement stone patterns

Figure 22 – Replacement stone patternsThe new Dutchmen were fabricated, delivered, and adjusted (Figure 23), set in place (Figure 24), and then mortared.

Figure 23 – Field adjusting marble edges Figure 24 – Dutchmen set in place

Figure 23 – Field adjusting marble edges Figure 24 – Dutchmen set in place

The process was completed for stone damage on each column (Figure 25).

Figure 25 – Multiple locations for Dutchmen

Figure 25 – Multiple locations for DutchmenTerra cotta repairs included synthetically patching the many chips and breaks (Figure 26). These were prepared and new material carved in place (Figure 27). A synthetic glaze was also applied over the repair.

Figure 26 – Terra-cotta spall

Figure 26 – Terra-cotta spall Figure 27 – Synthetic patching material being placed on terra cotta spall of Figure 26

Figure 27 – Synthetic patching material being placed on terra cotta spall of Figure 26Completed synthetic terra cotta patching was generally not perceptible (Figure 28).

Figure 28 – Terra cotta synthetic repair

Figure 28 – Terra cotta synthetic repairThe 2020 observations determined that the 2001 repairs have held up very well. There are no signs of failures to either the synthetic repairs or Dutchmen. The only faults that are evident are aesthetic. Several of the Dutchmen stand out because the new stone is brighter than the original. Figure 29 is one example of the Dutchman not weathering at the same rate as the original marble leaving a lighter color. In the future, these stones can be stained to better match the original columns if necessary.

Figure 29 –Columns with light-colored Dutchmen (2020)

Figure 29 –Columns with light-colored Dutchmen (2020)Figure 30 shows the main entrance to the building in 2020. The columns and entablature provide a marvelous appearance.

Figure 30 –Columns with light-colored Dutchmen (2020)

Figure 30 –Columns with light-colored Dutchmen (2020)Summary

Marvelous masonry lasts and stands the test of time. The enduring quality of the New York State Education Building is a testament to the original design, selection of first-class materials, and quality installation. With time, restoration processes are evolving and new repair materials are being developed. The 2001 restoration was expertly performed by the masons even with a significant winter effort. After over 18 years, the repairs and cleaning appear in excellent condition. It was an honor to have led such a project.

Acknowledgments

New York State Education Department

New York State Office of General Services (OGS)

New York State Dormitory Authority

Ryan Biggs | Clark Davis Engineering & Surveying, D.P.C. (restoration engineering)

DeBrino Caulking Associates (masonry restoration)