Tech Talk: Veneer Anchors For New Construction

Words and Photo Courtesy of the MCAA

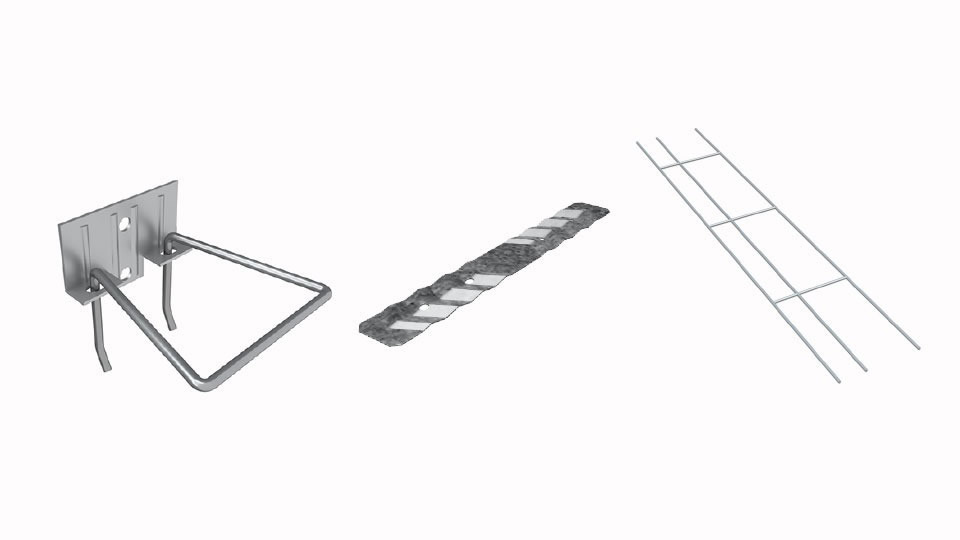

Figure 1. Left: Typical adjustable veneer anchor (Heckmann), center: typical corrugated sheet-metal anchor (Simpson Strong-Tie), and right: ladder-type joint reinforcing with side rod for anchoring veneer (Hohmann & Barnard).

Veneer anchors or wall ties are pretty much taken for granted on most jobsites. However, they have a critical function to perform – that of anchoring the masonry veneer to the backup and resisting out-of-plane loads applied in either direction to the veneer. Veneer anchors are not intended to provide any vertical support for veneer as this is typically provided by the foundation and/or periodic shelf angles.

With the trend towards wider cavities, due to continuous insulation between backup and veneer, the structural demand on veneer anchors is significantly increased and often the veneer anchorage will need to be designed or, at least, reviewed by a professional engineer. On the other hand, simple empirical methods can be used to meet code requirements for veneer anchorage in most situations.

The 2013 Building Code Requirements and Specifications for Masonry Code (TMS 402-13/ACI 530-13/ASCE 5-13) recognizes five types of anchors: corrugated sheet-metal, sheet-metal, wire, adjustable and joint reinforcing and has minimum requirements for each type related to dimensions, embedment and cover. Ladder-type or tab-type joint must have a minimum wire size of W1.7 with welded cross wires spaced at a maximum of 16 inches on center.

Truss-type joint reinforcing may restrain differential movement between backup and the veneer and is not recommended. Minimum embedment for all anchor types is 1 ½ inch into the veneer, and mortar or grout cover to the exterior face should be a minimum of 5/8 inch. The required corrosion protection for veneer anchors can be provided by mill or hot-dip galvanized coatings, epoxy coatings or by using anchors fabricated with either AISI Type 304 or Type 316 stainless steel.

The prescriptive requirements below correspond to low seismicity areas in Seismic Design Category (SDC) A and B only. There are separate, cumulative veneer anchorage requirements imposed in each of the higher Seismic Design Categories C through F. Basic prescriptive requirements for veneer anchor spacing are also limited to areas where the calculated wind velocity pressure is 40 pounds per square foot (psf) or less using ASCE 7, Minimum Design Loads for Buildings and Other Structures.

This limits the application of the basic prescriptive requirements to areas with moderate wind velocities. Additionally, the distance from the inside face of the veneer to the structural backup is limited to 4½ inches or less for adjustable ties on cold-formed steel framing and wire, adjustable or joint reinforcing over masonry backups and for all anchor types except corrugated sheet-metal anchors on wood framing. Corrugated sheet-metal anchors are limited to a 1-inch maximum distance between the inside face of the veneer and the exterior face of the sheathing.

As a result, corrugated sheet-metal anchors should not be used in cavities containing insulation. For adjustable anchors, anchors of wire size W1.7, and 22 gage corrugated sheet-metal anchors, each anchor must not support more than 2.67 square feet of veneer wall area. All other anchor types (meeting the minimum requirements) are allowed to support up to 3.5 square feet of veneer. For all anchors, the maximum spacing allowed is 32 inches on center horizontally and 25 inches on center vertically, as long as they meet the maximum area requirements described above.

Additional anchors are required around openings larger than 16 inches (in either direction) and should be within 12 inches of the opening and at a maximum spacing of 36 inches on center. The last prescriptive requirement is that the mortar bed thickness must be at least twice the thickness of the embedded anchor.

Additional prescriptive requirements are provided for areas in Seismic Design Categories A and B where the wind velocity pressure exceeds 40 but not 55 psf (per ASCE 7) for buildings with a mean roof height of 60 ft. or less. In these high wind areas, the maximum area of veneer supported by each anchor is reduced to 70% of the area limits described above.

This corresponds to a maximum wall area of 1.87 square feet for adjustable anchors, anchors of wire size W1.7, and 22 gage corrugated sheet-metal anchors. Similarly, the maximum wall area per anchor for all other veneer anchors is reduced to 2.45 square feet. The additional requirements in high wind areas are to space anchors at a maximum spacing horizontally and vertically of 18 inches on center as long as they meet the reduced maximum area requirements. Additional anchors are also required around openings larger than 16 inches (in either direction) and should be within 12 inches of the opening and at a maximum spacing of 24 inches on center.

Anchor attachment to each backup type is prescribed in TMS 402-13. For wood framed construction, each anchor must be installed with a corrosion resistant 8d common nail or other fastener having an equal or greater pullout strength. The fastener must be installed into the stud, not just the sheathing. For corrugated sheet-metal anchors, it is critical to locate the fastener within ½ inch of the 90 degree bend in the anchor to reduce mechanical play.

Adjustable anchors should be used with cold-formed steel framing backup that has a minimum base metal thickness of 0.043 inch (18 gage) and the anchor attached with at least one No. 10 corrosion resistant screw or equivalent with equal or greater pullout strength. Wire or adjustable anchors and ladder-type joint reinforcing are permitted with a masonry back up. Adjustable anchors are the only type permitted for concrete back up.

The cumulative requirements for Seismic Design Categories C through F are also detailed in TMS 402-13. For locations in Seismic Design Category C, the sides and top of anchored veneer walls or panels must be isolated from the back up structure to prevent lateral seismic forces from being transmitted to the veneer. In Seismic Design Category D, the area of wall supported by each anchor should be reduced to 75% of the basic (moderate wind) prescriptive requirements, in addition to the isolation required in SDC C.

The maximum spacing requirements are unchanged. Further, for attachment to wood framing the fastener must be anchored with a corrosion-resistant 8d ring-shank nail, a No. 10 corrosion-resistant screw or a fastener with equivalent or greater pullout strength. In Seismic Design Categories E and F, the requirement of SDC D apply, in addition to the requirement that the weight of each story of anchored veneer be supported independently.

In summary, veneer anchors are not a trivial component in modern veneer construction. They perform a critical function and, as a result, there are numerous requirements that must be met in order to be compliant with today’s building codes. Keep in mind the numerous constraints on the use of the prescriptive requirements including: seismicity, wind pressure, building height, cavity width, and the compatibility of backup and anchor type. If the prescriptive requirements are not applicable, for example, the cavity width exceeds 4½ inches to accommodate rigid insulation, the veneer anchorage should be engineered to resist design loads.