Marvelous Masonry - Peru Celebrating Masonry’s Heritage

Words: David Biggs

Words & Photos: David Biggs PE, SE unless otherwise noted

In 2018, I had the opportunity to attend the 11th International Conference on Structural Analysis of Historical Constructions (SAHC) in Cusco, Peru. Held biennially, SAHC conferences are highly prestigious international events that allow sharing and dissemination of research and practice among academics, architectural and engineering practitioners, researchers, and others involved in maintaining our heritage environment. The theme of the conference was “An Interdisciplinary Approach” which emphasized the importance of the involvement of a variety of disciplines in the task of conserving and restoring heritage structures. As you would expect, masonry construction is a primary focus of the conference.

Figure 1 – Cusco

This conference, like previous SAHC conference, was held in a historic site. The history of the Cusco area dates back to at least 1,000 BC and is one of the oldest continuously-inhabited cities in the western hemisphere. Since its founding, several cultures have occupied and expanded the region including the Marcavalle, Chapanata, Qotakalli, and Killke. Finally, the Inca civilization developed c. 1200 AD and they built the city of Cusco between two rivers (Figure 1). The original city in yellow was zoomorphic (shaped like a Puma). The city expanded from there. The three rivers were subsequently buried by later generations.

In 2018, I had the opportunity to attend the 11th International Conference on Structural Analysis of Historical Constructions (SAHC) in Cusco, Peru. Held biennially, SAHC conferences are highly prestigious international events that allow sharing and dissemination of research and practice among academics, architectural and engineering practitioners, researchers, and others involved in maintaining our heritage environment. The theme of the conference was “An Interdisciplinary Approach” which emphasized the importance of the involvement of a variety of disciplines in the task of conserving and restoring heritage structures. As you would expect, masonry construction is a primary focus of the conference.

This conference, like previous SAHC conference, was held in a historic site. The history of the Cusco area dates back to at least 1,000 BC and is one of the oldest continuously-inhabited cities in the western hemisphere. Since its founding, several cultures have occupied and expanded the region including the Marcavalle, Chapanata, Qotakalli, and Killke. Finally, the Inca civilization developed c. 1200 AD and they built the city of Cusco between two rivers (Figure 1). The original city in yellow was zoomorphic (shaped like a Puma). The city expanded from there. The three rivers were subsequently buried by later generations.

Cusco sits at an elevation of over 11,000 feet in the Andes Mountains of South America. It was the capital of the Incan Empire whose prominence was primarily from 1438 to 1533 AD. Spanish conquest began in 1533 and was completed by 1572.

The Incas were master builders of masonry structures using adobe and stone. Their craft was derived from previous cultures and the Incas continued the mastery. The Spanish brought their architecture and blended it with the Incas.

Masonry abounds throughout Cusco and Peru. Let’s take a look at some stone masonry in Cusco. Figure 2 shows the Plaza de Armas in the historic center of Cusco. It is distinctive for being one of the few plazas in the world with two cathedrals.

The Cusco Cathedral on the left was constructed 1559-1654. The Spanish demolished the Inca temple on its site and erected the Roman Catholic cathedral on its foundation in an attempt to eliminate the Inca religion and impose Christianity. The cathedral on the right is the Jesuit’s Church of the Society of Jesus. Its construction began in 1557.

Figure 2 – Cusco Plaza De Armas

Figure 3 - Cusco Cathedral

Figure 3 shows the façade of the Cusco Cathedral in the Gothic-Renaissance style. Many of the stones were taken by the Spanish from another historic site, Sacsayhuamán, on the northern perimeter of Cusco (head of puma, Figure 1). Both historic Cusco and Sacsayhuamán are UNESCO World Heritage sites.

The Spaniards used mortar to build their walls. In 1650, an earthquake (estimated magnitude 7.7) destroyed many parts of the city and the cathedral was badly damaged. A painting, Cuzco at the Time of the Earthquake of 1650 documents the destruction and is available online and resides in the Bridgeman Art Library in New York City.

Subsequent major earthquakes in Cusco have been magnitude 6.5 (1943), 7.0 (1950), 6.1 (1986) and 5.0 (2014). Each damaged arches, vaults, and towers on the cathedral. Seismic retrofits were performed in 1951-1953, 1987-1989 and again 1991-1995. Researchers in 2004 stated that additional retrofits to the domes are needed to prevent collapse under a future earthquake.

As mentioned, much of the stone for the cathedral came from Sacsayhuamán (Figure 4) which is well known for its megalith limestone stonework dating back to 1100 AD. Some stones weigh over 110 tons yet they were laid without mortar and the joints are paper thin. Cutting, fitting and moving the massive stones for the initial construction was an amazing task. The original stones were modified and repurposed by the Spaniards for the cathedral.

There is a 40-minute documentary "The Living Stones of Sacsayhuaman" (https://topdocumentaryfilms.com/living-stones-sacsayhuaman/) which highlights the megalith stone constructions.

Figure 4 – Megalith stones at Sacsayhuamán. (Credit: Diego Delso [CC BY-SA 4.0 (https://creativecommons.org/licenses/by-sa/4.0)]

Figure 5 - Church of the Society of Jesus

Figure 5 shows the façade of the other cathedral, Church of the Society of Jesus, constructed in the Baroque style. The Spaniards built upon the site of another Inca palace. This cathedral was also badly damaged by the earthquake of 1650 but was rebuilt by 1668. The towers and entry portal are adorned with ornate stonework.

Cusco has many more historic sites worth a visit. However, most tourists visit Cusco on their way to Machu Picchu, an Incan site that continues to attract thousands of visitors each year. The trip to Machu Picchu can be a challenge or an adventure. I chose the train ride adventure from Ollantaytambo Station which is about a 1-1/2 hour drive from Cusco. No straight freeways here, every road in Peru has the next turn in sight. The train arrives at Machu Picchu Pueblo also called Aguas Calientes at the entrance to Machu Picchu National Park. In elevation, you start at Cusco (11,152 ft) and proceed to Ollantaytambo (9,160 ft) then onto Aguas Calientes (6,690 ft) and it ends with a final bus ride or hike up to Machu Picchu (7,972 ft). If you skip the train and spend a week hiking the Inca trail, you could get as high as 13,828 feet.

The first views of Machu Picchu are breathtaking. The Incas began construction c. 1430 but abandoned it in 1572 after Spanish conquest before it was completed. It was not until 1911 when locals led an American archeologist, Hiram Bingham, to the site and the world discovered this marvelous example of stone masonry.

Figure 6 – Machu Picchu

Figure 6 is the view most often seen in travel magazines taken from a spot above the city from the agricultural area. Like many of the marvelous sites we’ve reported on in previous articles, the masonry has survived for centuries yet the timber roofs of the buildings are long gone.

Figure 7 – Terraced walls

The agricultural section of the city is a wonder of terraces made with stone retaining walls (Figure 7). The terraces provide slope stability and growing area.

Throughout the site, the masonry is such amazingly good condition that you think it’s a restoration. But, it’s not! Much of the construction is original and constructed without mortar. I was impressed by both the condition of the individual stones as well as the walls themselves.

- The individual stones are in excellent condition, with almost no deterioration. There are several reasons for this. The primary reason is the excellent quality of the stone. The Incas used local stone at each site. The mountain at Machu Picchu is an unending source of granite so most of the city is granite. Figure 8 shows the quarry of unused stone at Machu Picchu.

Figure 8 – Granite quarry on the mountain

Mr. Vincent Lee, a noted American mountaineer, architect, Andean explorer, and scholar of megalithic monuments from Colorado, has traveled the world studying stone construction including that of the Incas. His books (www.vincent-lee.com) are treasures of information and personal insight. In personal communications, he stated that the Incas used local, but very durable, materials including the granite at Machu Picchu, rhyolite and basalt at Ollantaytambo, andesite in Cusco, hard blue limestone at Sacsayhuamán, and others. His only observation of weathering deterioration has been with the sandstone at Oroncota in Bolivia.

Figure 9 – Granite with tooling marks

Figure 9 shows a stone that Machu Picchu guides purport to be a remnant of Incan stone fabrication. They attribute this to what they say are the visible tool marks and the splitting line. However experts, including Mr. Lee, state that there is no evidence of the Incas using wedges to split stones prior to the arrival of Europeans. The Incans picked their stones by either prying them from shattered formations or selected them from talus slides (the broken rock at the base of cliffs or rock formations).

A second reason for the minimal stone deterioration is the climate. Despite the elevation, Machu Picchu has a temperate climate of between 36° and 79°F. Seasons are mainly identified by wet and dry. So there are few freeze-thaw conditions that could cause deterioration. Thus, the stone endures.

- The walls have survived centuries despite being unattended from about 1572 into the 1900s. Photographs from the discovery in 1911 were published by National Geographic in 1913 and show the timber roof structures rotted away, but the masonry walls remain. As expected, the tops of the walls were deteriorated from being exposed to the weather after the roofs collapsed. Figure 10 shows the tops of several walls which have been restored without capstones. Figure 11 shows sections of walls with capstones.

Figure 10 – Top of restored walls

Figure 11 – Capstones on level wall (left) and gables (right)

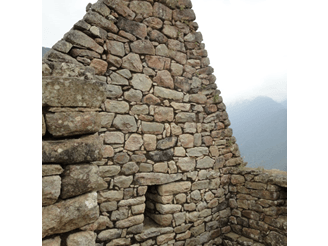

The Incas built their stonewalls in a variety of ways depending on the use of the structure. Similar to many other cultures, a very common Incan construction method used rough cut stone with chinking (also called hearting) of small stones to fill the gaps along with mud (Figure 12). You’ll also note that most of the stones are laid “two over one” to minimize any continuous vertical joints. That knits the wall together in a running bond that is common in modern mortared masonry.

A key feature to the performance of any dry laid wall is the contact between stones. We are familiar with mortared walls that provide complete contact of the stones through the use of mortar. For walls without mortar, the contact is a function of the type of stone used and the craftsmanship of the builder. The Incas used craftsmanship and worked the stones to optimize the contact.

Figure 12 – Mortar-less stonewalls site wall (left), gable end of the building (right)

To illustrate the importance of stone selection to construct a dry laid wall, Figure 13 shows a modern New England stone wall constructed with rounded stones. No working of the stones was used. While it is nicely done with “two over one” jointing, the rounded nature of the stone reduces the possible contact between stones. Chinking is essential to improve the interlock.

Figure 14 shows another modern New England wall, but constructed with naturally flat stones with little chinking. Flattened stones provide a much more stable wall than the one shown in Figure 13 because there is simply more direct contact between the stones. There are also numerous through stones to tie the leaves (wythes) together. As seen in Figure 12, the Incas did not have naturally flat stones at this site but flattened the stone surfaces to get maximum contact. They flattened the surfaces by pounding with other stones. A testament to Incan construction is that the walls have survived centuries of weathering and earthquakes yet still remain strong and stable.

Figure 13 – Stone wall with rounded stones

Figure 14 – Stone wall with flattened stones

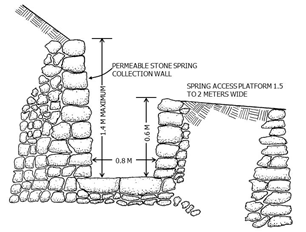

The Incas used masonry construction for much more than just basic walls. Figure 15 was provided by Mr. Ken Wright, a highly esteemed civil engineer who is the Founder and Chief Engineer of Wright Water Engineers, Inc., a Denver consulting firm specializing in water resources and municipal utility design. Ken and his wife Ruth have conducted paleohydrological research at Machu Picchu and other Peruvian sites for over thirty years. One of his many books, Machu Picchu: A Civil Engineering Marvel is filled with his insights into this marvelous masonry site.

Mr. Wright documented the Incan use of “permeable stonewalls” to collect spring water and runoff into open stone channels. It’s amazing that the Incas intended the water to filter through the walls yet the moving water has not dislodged the stones. how many engineers or contractors would build that way today?

Figure 15 - permeable stonewalls (Courtesy of Ken Wright)

Figure 16 shows some of the open water channels made from stone that still feed the city.

Figure 16 - Open stone channels (Courtesy of Ken Wright)

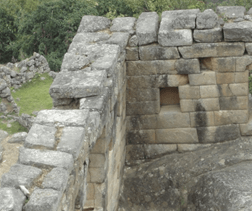

For more important structures such as palaces, temples, and grand entrances, the Incas also used dressed stone. Figure 17 shows the amazing granite stones of two temples. With little ornamentation, the Incas used the masonry as design features.

Figure 17 – Two Incas temples at Machu Picchu: Temple of the Sun (left) and Principal Temple (right)

The quality of the stone joinery is truly marvelous. Figure 18 shows a close-up. For small stones, the perfect fit has been explained by two possible methods of “trial and error”. For the first method, the interface of two stones is repeatedly worked until a fit is achieved. For the second method, a clay model is made of the previously set stone surface. Then the second stone is worked to that configuration. For both methods, constant working the stone and test fitting was required. Experts will point out there is no direct evidence for using clay models; none would have survived.

As can be seen in Figure 18, beating the head and bed surfaces stones into the desired shape resulted in rounded corners but with a perfect fit. You’ll almost never see a 90-degree corner in Incan construction.

Figure 18 – Dressed stone joinery

Trial and error fit checking was essential for joining stones but required constant moving of the stones. While practical for smaller stones, how was it possible for megalith-sized stones? Moving these stones only once would have been an amazing accomplishment. How could they constantly be moving and fitting every stone by trial and error? Mr. Lee has proposed a theory that the large stones may have been fabricated by “scribing” the massive stones to each other before pounding and shaping the surfaces thereby fitting prior to lowering them into place with one move. The Incas were marvelous masons; that is clear through the quality of their work and that experts are still unsure of the exact methods used.

In 1934, Morris K. Jessup wrote in American Anthropologist about the Inca stonework and pointed out that the Incas rounded the face surface of many of their stones for aesthetic purposes. That exposed surface rounding added a great deal of extra effort to fabricate and improved the aesthetic effect which is also visible in Figure 18.

One additional method used by the Incas included a mix of rough stones and more dressed units as seen in Figure 19 at the doorway entrance to the city. Clearly, the Incas used stonework as architecture.

Figure 19 – City entrance

Figure 20 – Agricultural terraces also used for slope stability

Figure 20 shows more of the terraces and reconstructed agricultural buildings that are six to eight feet tall. Ken Wright documented these as being mostly 32 inches or thicker. The 32-inch dimension shows up often n Incan construction. It was a unit of measure called the “sikya”. The sikya is the distance from a person’s centerline to their outstretched fingertips.

Figure 21 – Terrace walls and steps

Figure 21 shows a wall close-up. Notice the mixture of smaller rough stone and the larger stones, partially dressed, but never set flat. Another unique feature that is visible is the cantilever stones set into the wall that act both as the header for the wall and steps to allow access from one terrace level to another.

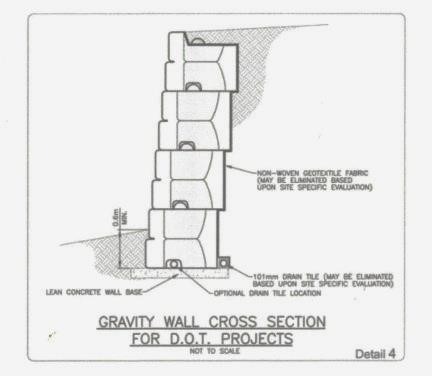

The structural integrity of these walls is marvelous! Both Messrs. Wright and Lee highlight the importance of battered walls in Incan construction. Generally, the exterior face of this gravity slope into the hillside at a 5 to 6% slope. This magnitude of batter has been found in the construction of numerous ancient civilizations such as the Greeks, Phrygians, Egyptians, and others. It is no surprise that we find some modern-day gravity retaining walls with a set batter of approximately 6% (Figure 22) and a wall thickness close to the 32 inches of the Incas (Figure 22).

Figure 22 – Modern gravity retaining wall with approximately 6% batter (credit - Strong Stone, LLC)

To understand the structural performance of these walls, I performed an elementary analysis. Based upon information from Mr. Wright’s book “Moray, Inca Engineering Mystery”, we know the Incas created a drainage base below and behind the walls that prevented hydrostatic pressure. Therefore, a global analysis using an active pressure of 35 psf and 32-inch thick walls was performed. For the six-foot walls, the safety factor of overturning was approximately 2.5; for eight-foot walls, that safety factor reduced to about 1.4. These are excellent values and the walls work because the Incas built them well headered together to function similar to a solid wall. The contact area between courses distributes the horizontal shear such that a friction value of approximately 0.5 prevents sliding.

Many theories have been presented as to how the Incas moved the large stones. Mr. Lee published “Building Big With Next To Nothing” that is a most interesting book on megalith structures in Peru, Easter Island, and Egypt. While no one knows for certain how the massive stones were transported, Mr. Lee does a great job of presenting various options and their challenges. Ultimately, he presents solutions that are plausible and repeatable. If accurate, the possible use of stone sleds and “rowing” stones into place are a testament to Inca ingenuity as well as the creativity of Mr. Lee. Like to know more? Check out his book.

We have only been able to touch on a few marvelous sites in Peru; there is so much more. Want to visit Machu Picchu? Don’t like traveling or crowds? Don’t have the time or funds?

Check out Google Earth’s Street View

(https://www.theguardian.com/travel/2015/dec/03/machu-picchu-google-street-view-peru). There are also many YouTube videos that walk you through this marvelous masonry site.